Antenna Cluster Planning

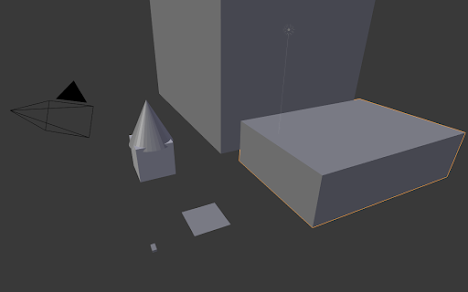

For vertical diving proximity, use 3-D modeling of the mission scenario sketch. The example with Blender is in the picture on the right. The small matchbox at the lower left corner is the base station. And, based on the mission scenario, the RF-control/FPV antennas are arranged to prevent internal interference and obstructions.

For vertical diving proximity, use 3-D modeling of the mission scenario sketch. The example with Blender is in the picture on the right. The small matchbox at the lower left corner is the base station. And, based on the mission scenario, the RF-control/FPV antennas are arranged to prevent internal interference and obstructions.

For surface proximity, ground obstacles were viewed in mapping software.

Zooming in reveals an extra outcrop of rocks blocking LOS of the 1km proximity site.

The land survey revealed a radio LOS dead zone packet during low tides.

The aerial survey avoided the dead zones with large margin accordingly.

This video also demonstrates the inadequacy of the single RF control antenna parallel to the boom. The craft crashed at the end with an RXLOSS warning.

However, during the actual proximity mission, the high tide prompted acute steering toward the land. Without an on-location survey, the proximity mission during high tide failed (drone loss in the sea) with altered path obstacles.

The high-tide view of the crash site immediately after the craft loss shows no sandy shoreline.

The rendezvous plan record was photographed immediately after the crash. Actual dive at 6336, 6090 by memory.

.png)

The red lines and red curves rest on the obsticale rock outcrop that blocked RF signals.

The view of the ground station is used to identify the on-location perspectives.

The off-course path on-location perspective is identified next to the original planned (good LOS throughout) one. The doggy footprint trace is identified as the crash location.

The large rocks forming a diamond shape are a reliable visual landmark for an unobstructed path. A storm dispersed pebble stones in the picture.

Then, the proximity mission succeeded in the next attempt.

This video also demonstrates the interchangeable antenna of TrueRC and Runcam Link, with a 25Mbps data rate and a 25ms delay 1+ km away at 0:26, 0:30, and 0:35.

The in-car battery and VRX were under a white food bag to cool them in the sun during the mission.

Dive Proximity Punchout Runway Needs To Go Parallel Or Go With Waves

An example of a drone lost when the punchout runway goes against the wavefront is here. At 1:30, two pedestrians were walking onto the planned punch-out "runway" at the dive target, at the center of the four-rock diamond. Planned path (42.6336, -70.6095) toward (42.6335, -70.6102).

An improvised plan-B reversed the punchout direction, and the dive started at 2:50 (42.6335, -70.6102) toward (42.6336, -70.6095). The reversed punchout was met with a surge front instead of the planned parallel runway with the surges.

Lesson learned: Improvised plan B seldom works. The comparison pictures of the planned and improvised paths are as follows.

|

|

|

The unexpected "ground" rise of the surge front required visual acuity for quick aversion. Still, I wore a pair of dark sunglasses with mirror plating due to the intense sunlight at the ground station (inside a car) of perfect weather. The "ground" appeared as a grey mat on the FPV monitor (16-inch gaming monitor).

Lesson learned: The ground station requires proper sun shielding over the FPV monitor to give consistent visual cues of piloting. I have ordered the cockpit-grade sun shielding for my car https://www.amazon.com/dp/B084QHVL6S?ref=ppx_yo2ov_dt_b_fed_asin_title&th=1

Be Skeptical Of Space Weather Kp Value

Continuing from the previous discussion of punch-out direction, the UAV Forecast app showed a red warning for Kp 6.0 on the dive day. The high Kp value is supposed to disrupt GPS, but the OSD latitude/longitude is just fine in the dive video.

Lesson learned: Concentrate on GPS-visual navigation and don't get distracted by space weather.Aim The Antennas At The Distant Lowest Altitude Level Of A Mission

Continuing from the previous discussion of punch-out direction, this particular mission has antennas on a tripod on the car roof. I experienced blurred FPV feed when the patch antenna was aimed at the dive target sky level during a trial before the mission. The actual mission result video shows less blurring when the patch antenna aims at the ground level of the dive target. It is well known that long-distance signal degradation first occurs near the ground, and that the signal is always much stronger in the sky. So, the antenna needs to aim at the ground.

Free General Weather App To Predict Wind And UAV Forecast For Wind Profile

The UAV Forecast is less accurate than general weather apps for planning a few days ahead.

The following 3 pictures show that, 1.5 days ahead of a Saturday, the general forecast predicted a windy Saturday morning, while the UAV Forecast predicted a calm Saturday morning.

And the actual Saturday morning, 7AM, was windy, as shown in the following. The UAV Forecast revised its wind speed to 200% of the forecast.However, UAV Forecast provides wind speeds on the ground and in the sky, sometimes a 500% difference between them. The example sunset time here shows that GWeather reported a wind speed of 8mph, while UAV Forecast reported wind speeds of 5-6mph on the ground and 32-33mph in the sky.

The mission at that sunset time tested whether the production build's cusped airfoil stalls in red warning windy conditions with a stipulated 8-degree collective pitch angle. The real, actual wind speed (nearly windless) on the ground matched UAV Forecast's report when I stepped outside the car to deploy the craft. The mission video, between 0:00 and 0:12, shows a high down-pitch attitude keeping the craft in place, confirming that the wind in the sky was indeed quite strong, as reported by UAV Forecat.

The production build's cusped Joukowsky airfoil was verified without a stall in red warning wind conditions using UAV Forecast. The verification mission could not be done with the general weather GWeather app.Nonetheless, the general weather app often, but not always, can predict a calm, wind reversal time several days ahead with an accuracy of within 1.5 hours. UAV Forecast misses the time by 200% to the accuracy of the Google Weather app. The following is an example of predicting a wind reversal three days ahead for Wednesday at 11:00 AM.

The actual Wednesday wind calmed at 11 AM, and the reversal occurred at 12 noon, as follows.RF Transmitter Setup

The alternative micro sized transmitter module wiring pictured here.

The alternative Frsky R9M module can be set to output 500mW using alternative Taranis QX7's transmitter's regular power pins without external power source, as shown in this video,

This flight sequence rehearses the mission plan, diving from 330 feet east, 440 feet north, ground distance 550 feet, air distance 1000 feet, relative to ground station. 3 flips above the landing patch area. Level traversal between 330 feet east, 440 feet north, and 330 feet straight east.

This flight sequence rehearses the mission plan, diving from 330 feet east, 440 feet north, ground distance 550 feet, air distance 1000 feet, relative to ground station. 3 flips above the landing patch area. Level traversal between 330 feet east, 440 feet north, and 330 feet straight east.

Video Receiver Setup

As a video demonstration here, antennas are inside the car with no obvious signal degradation by the windshield, which is made of glass and PVB plastic material that are not known to block WiFi signals with far lower frequencies than infrared (which is known to be blocked by glass and PVB). This setup is used by all mission videos in all chapters of this blog unless otherwise explicitly stated.

The gaming monitor automatically adjusts its refresh rate to the highest the VRX can generate, as pictured here. There is no obvious way to change this, which is a good thing because you always get a consistent low delay. You can't mess up even if you want to.

The gaming monitor automatically adjusts its refresh rate to the highest the VRX can generate, as pictured here. There is no obvious way to change this, which is a good thing because you always get a consistent low delay. You can't mess up even if you want to. The brand-new VRX cost is here. However, it is much cheaper when you purchase it as part of a combo with a VTX. And our spreadsheet accounting uses the cheaper combo price and splits the low price into its component parts, as is practiced in the parts discussion chapter.

The brand-new VRX cost is here. However, it is much cheaper when you purchase it as part of a combo with a VTX. And our spreadsheet accounting uses the cheaper combo price and splits the low price into its component parts, as is practiced in the parts discussion chapter.In-Car Battery Charging

Fight batteries should be warmed/cooled with car vent before charging in cold/hot temperatures. When the car engine is offline, the car battery voltage has a slight drop, so the flight battery charger needs to be set to output below 1 amp to prevent low low-voltage cut-off during charging. The charger wires are hung by velcro stripes without a sticky backing.

TalentCell power bank YB1206000-USB has overheating protection. Keep it on the dashboard and plug in the charging plug year-round. If it is overheated by the sun, wait until it cools down to power on.

Walksnail 1S Lite USB Adapter Compatible With HD V2 Cameras.

As long as the plug is aligned with the socket to the left most pin when viewing from the right side of the craft toward the left side of the craft.

Box 17.5 Inches Long And 3 Inches Thick Or Larger

Cut the cardboard by the green line and the seam line pointed by the arrow, cutting the box in half while keeping a lid.

FPV Feed Flight Path Tracking

The raw FPV DVR recorded mp4 of the tail-spin crash with fishbowl optical illusion is saved at googledrive https://drive.google.com/file/d/1IchzErZsqhmW0qukS_ZLuJz3CpO4A27t .

When viewed in Android MX Player or the FPV headset, the last 3 frames used to track down the wreckage is not available frame-by-frame. A laptop or Chromebook with Avidemux.AppImage is needed to step in the last 3 frames.

Avsaase/walksnail-osd-tool From Github

Compatible with Chromebook for crash GPS searching with frame-by-frame video of a crash.

Anthwlock/untrunc From Github

Compatible with Chromebook for crash-interrupted VRX .mp4 file un-corrupting. The code is based on original ponchio/untrunc that has bug compatibility with Chromebook.

248 git clone --recurse-submodules https://github.com/ponchio/untrunc 249 cd untrunc 250 vim ../untrunc-master/README.md 251 ls 252 cd libav/ 253 ls 254 ./configure 255 sudo apt install yasm wget 256 ./configure 257 make FF_VER=3.3.9 258 vim ../untrunc-master/README.md 259 cd ../ 260 vim ../untrunc-master/README.md 261 grep g++ ../untrunc-master/README.md 262 vim ../untrunc-master/README.md 263 g++ -o untrunc -I./libav file.cpp main.cpp track.cpp atom.cpp codec_*.cpp codecstats.cpp codec.cpp mp4.cpp log.cpp

-L./libav/libavformat -lavformat -L./libav/libavcodec -lavcodec -L./libav/libavresample -lavresample -L./libav/libavutil

-lavutil -lpthread -lz -std=c++11

264 sudo cp untrunc /usr/local/bin 265 which untrunc 266 untrunc 305 cd ../../ 306 cd MyFiles/Downloads/ 307 untrunc ./AvatarS0086.mp4 ./AvatarS0087.mp4

.png)

.png)

.png)