Use Fixed RPM With Wide Rotor As Power Surge Capacitor

| 250 grams Takeoff | HD Video | 30 minutes Endurance | Sustained Vertical Dive | |

| DJI Mini Pro | ❌ | ✅ | ✅ | ❌ |

| DJI Mini Without Phone | ✅ | ❌ | ✅ | ❌ |

| DJI Mini With Phone App | ✅ | ✅ | ❌ | ❌ |

| DJI Neo | ✅ | ✅ | ❌ | diffi-culties |

| DJI Avata | ❌ | ✅ | ❌ | ✅ |

| Flywoo LR4 With Lipo | ✅ | ✅ | ❌ | ✅ |

| Mayfly V2.0 | ✅ | ❌ | ✅ | (no test) |

| Flywoo LR4 With Li-Ion | ❌ | ✅ | ✅ | diffi-culties |

| ⭐Converged IoT | ✅ | ✅ | ✅ | ✅ |

The wide rotor of the helicopter acts as a flywheel for power surges and high-G maneuvers. In the video on the right of the same build (and the same battery pack), the craft was subjected to a terminal velocity dive punch-out at 2:39, and there is no visual difference between this punch-out and the extreme robotics build's punch-out with a "120C" marked battery.

Use Popular Hand-Held Electronics Cells For Their Lightweight And Low-C-Cutoff-Protection

Moderate C-Rated batteries are "low-C" by the hobby industry due to marketing pressure. According to the US Department of Energy, https://www.energy.gov/eere/vehicles/articles/reducing-reliance-cobalt-lithium-ion-batteries, the leading lithium-cobalt battery for passenger cars has a nominal energy density of 190 Wh/kg, with reasonably thin-layered electrode construction at a moderate discharging rating, and reserving 10% electrode to prevent damage, equating to 190 Wh/kg x 90% = 170 Wh/kg. We use airsoft gun batteries, as the device is optimized for lightweight. And the frequent product updates utilize the latest battery technology. The half-hour endurance video with 4S 1.1 Ah cells has 3.55 V x 4 x 1.1 Ah = 15.6 Wh with an energy density of 15.6 Wh / 0.0919 kg = 170 Wh/kg, matching the leading car battery chemistry.

In contrast, the 95-C batteries with very low internal resistance have true cell voltages of 2.99-3.00V, nearly identical to the displayed 2.98V during force landings in the following test video, and hence the damage. This particular mission used a stipulated collective pitch limited to 8.2 degrees (OSD "throttle" 50) with production cusped airfoil blades.

Off-The-Shelf Endurance Optimization Oxy2 193mm And Microheli 180mm Plastic Blades Interchangeable

The prototype endurance build with Tattu1000(same as GensAce900) created a calibration data point for the Oxy2 210mm orange blades (479mm diameter) in the manufacturer's Sokolov propeller efficiency data set. The following paragraphs figure out that the 479mm diameter Oxy2 rotor is equivalent to a 13.5-inch Sokolov propeller.

The prototype 4004 kv400 motor with Oxy2 210mm blades has an efficiency of about 14.7 g/W for 250g lifting, servo+RX+CC3D FC 145+30mA, Baby turtle 380mA, VTX 200mW, combined at (0.145A+0.03A+0.38A+0.2A)x5V=3.78W, tail 1.44W with 21.2g thrust at, coincidentally, the same as main rotor, 14.7g/W. Gross power is 22.2W, 250g/(22.2W-3.78W-1.44W)=14.7gW. We plot manufacturers, T-Motor, Sunnysky, and HGLRC's' published motor mass and efficiency data to figure out the trend of different build combinations' parameters in the data curves,

T-Motor 4004's data is saved in https://drive.google.com/file/d/1u8NkHY28v4AklgQdXVgva0rvAXevIcff/ ,

T-Motor 2806's data is saved in https://drive.google.com/file/d/1A3C4TgKU-0X7GzRMv7PgJEgXHwu2BZ2c/ ,

Sunnysky 4004 400kv's data is saved in https://drive.google.com/file/d/1pYOJN9Hi-93svuun-8ODcXMY-UGgvON8/ ,

Sunnysky 4004 300kv's data is saved in https://drive.google.com/file/d/1xwbcVjCucTQAQFk8mq_o6eJbOfekKUEO/ ,

Sunnysky 2806 400kv's data is saved in https://drive.google.com/file/d/1MKCFu733HeZotZHhqp3N-I6adnCU65xG/ ,

Sunnysky 2806 650kv's data is saved in https://drive.google.com/file/d/1xpaYDaShMJg4fl07ka_vFqt4RPkkexjF/ ,

HGLRC 1303.5's data is saved in https://drive.google.com/file/d/1F2D4R6p1V8eqaQ5DHQGh-GXK_b36V62K/ ,

SParkhobby 1303.5's data is saved in https://drive.google.com/file/d/1ceFDKYo8B5uGcjp6UcM5C6dPKCF6AHe9 ,

Our prototype rotor's efficiency is equivalent to the 13.5-inch drone propeller's efficiency in terms of the same torque, RPM, mechanical, and electrical efficiency. So, the question is how to shift the prototype 4004-motor-13.5-inch-prop combination and scale the rotor blade toward an overall more efficient craft, not just an efficient rotor, according to the efficiency trend curve.

According to https://www.researchgate.net/publication/339342177_Gemini_A_Compact_yet_Efficient_Bi-copter_UAV_for_Indoor_Applications , disk loading is inversely proportional to lifting power consumption efficiency. So, the Phython code of calculating the efficiency of the most efficient motor-propeller combinations for 249 gram lifting force to fit all manufacturer and experimented data is,

lifting_weight_per_watt = 14.7 * (propeller_span_x/13.5);

This formula's propeller_span_x is for blades with twisted and curved edges. This formula can be applied to heavier motors. For example, the 4004 kv300 motor has an efficiency of conservative estimation of 16.3g/W for 250g lifting force by the curve. And, the matching blade span width is 16.3/14.7*13.5 = 15 inches, which is close to the highest efficiency curve for the 4004 300kv motor.

The generalized formula can be applied to lighter, smaller motors, such as T-Motor AS2306 1500kV at 8.3 g/W efficiency and an 8-to-9-inch propeller. 14.7*8.5inch/13.5 = 9.25 g/W , which is close to the manufacturer's published efficiency of 8.3 g/W. For the HGLRC 1303.5 motor, the formula gives 14.7*3.67/13.5 = 3.9 g/W, also close to the manufacturer's published data.

The propeller_span_x is the diameter of 2-blade propellers with twisted and curved edges. For 3-blade propellers, because of utilizing the air column 3/2 times as often as a 2-blade propeller, the equivalent air column cross-section area should be considered 150%. So, the equivalent 2-blade diameter should be considered the square root of 1.5, which is 1.224 times the 3-blade propeller's diameter. And a 3-inch 3-blade propeller will be considered a 3.67-inch 2-blade propeller.

The phython code of the calculation is

craft_construct_mass = 111.0; #change it for a particulr craft constructions endure time curve

propeller_span_x = 13.5; #change it to slide the rotor width with in a endure time curve

motor_propeller_mass = 62.5 * (propeller_span_x/13.5)**1.5;

battery_cells_weight = 249.0 - craft_construct_mass - motor_propeller_mass;

battery_energy = 0.171 * battery_cells_weight;

lifting_weight_per_watt = 14.7 * propeller_span_x/13.5;

power_tran_power_consume_rate = 249.0 / lifting_weight_per_watt;

total_craft_power_consume_rate = power_tran_power_consume_rate + 5.2;

endure_time_minutes = battery_energy / total_craft_power_consume_rate * 60.0;

print (endure_time_minutes);

The motor and propeller combined mass can be calculated by the Python3 code

motor_propeller_mass = 62.5 * (propeller_span_x/13.5)**1.5;

. This formula excludes the motor shaft and propeller hub. The coefficient 62.5 is calibrated to the prototype build's measurements, a 13.5-inch-equivalent propeller producing 35 minutes of endurance. This formula is suitable for larger motors and smaller motors. For example, for the 4004 300kv motor of 50.5 grams, drone propellers of 15 inches are about 21-23 grams, which is readily available in the DJI Inspire 3 aftermarket. 62.5*(15/13.5)**1.5 = 73.2 grams = 50.5g + 22.7g. For the DJI Mavic Pro motor at 23.5 grams with a 5.3-gram, 8.3-inch propeller blade pair. 62.5*(8.3/13.5)**1.5=30.1g ~= 23.5g + 5g. For HGLRC 1303.5 motor, 62.5*(3.67/13.5)**1.5=8.9g ~= 6.5g + 1.9g (propeller)=8.4g. For a 2306 motor with an 8.5-inch prop as optimal, 62.5*(8.5inch/13.5)**1.5=31.2g, very close to the actual available parts weights of 25.8g +5.3g=31.1g.

Finally, according to the endurance efficiency trend curve, endurance can be improved by changing the helicopter rotor span to be equivalent to an 11.5-inch drone propeller at the pinnacle of the orange curve craft construct. The 2806 kv400 motors by either T-Motor, Sunnysky, or MAD Components fit the motor mass data points of the endurance curve, and a 12-inch propeller is close to the 11.5-inch calculation.

Unfortunately, attempting to use a 12-inch drone propeller with a twisted Sokolov airfoil and a 2806 motor failed. The propeller has 249 grams of thrust, similar to the original endurance build with a straight, symmetrical airfoil, at 100RPM above the designated 3300RPM. However, the gyroscopic effect required for single-rotor mechanics is too weak to have stable craft control, so, as shown in the pictures below, large brass ballasts at 1mm thickness were added.

But the gyroscopic effect is still too weak, as shown in the video above from 5:00 onward. The prototype IoT build has an angular momentum of 1/12*(14.6+5)/1000 * 0.472**2 * 2640/60*2*3.14 = 0.10, and the twisted Sokolov after ballast addition has 1/12*(13.8+5)/1000 * 0.327**2 * 3400/60*2*3.14 = 0.060. The popular twisted Sokolov airfoil couldn't work even if tweaking RPM and angle of attack to slightly less than optimal because, as shown in Xfoil graph, the tip of the propeller, after lowering angle of attack to -3 degrees so that lift is near zero, deviates away from the low drag pocket of aqua/orange curves at 7-10 degrees, giving larger drag than designated operating drag when the angle of attack is at the designated angle for high lift. The motor builds up heat severely with the tweaking's drag.

The slanted Clark-Y airfoil, pictured on the right, also suffers from the complex correlation between drag and lift of the twisted Sokolov airfoil. But what makes Clark-Y worse is that it is heavier than the straight, symmetrical prototype build. The advantage of the peak of the optimization curve by reduced blade and motor weights is largely canceled. In the picture on the right, you can see a flat surface of the blade root area, giving a fixed, designated angle of attack of the blade when the flat surface is level. At 3500 RPM, the 77 throttle (collective pitch) point is lower than needed to give the designated angle of attack. About 90 throttle points to make the flat surface level. And yet, the RPM is still low on giving adequate gyroscopic effect. And, when RPM is raised, and the angle of attack lowered further, motor overheating occurs because the Clark-Y airfoil has a larger drag than the operating drag when the angle of attack is lower than the designated angle.

Tungsten or uranium heavy material blades are the solution for the curved Sokolov airfoil. The craft becomes a flying knife for military strike weaponry, not a commercial million-unit deployment.

The twisted Sokolov airfoil couldn't work even if tweaking rotor diameter to slightly less than optimal to gain gyroscopic effect and more optimized industry battery construction in the next video because the relationship between drag and attack angle is complex.

In the video on the right, the diameter is lowered to 9.5 inches, and the motor is changed to 2306. The RPM is designated to be 5000, and endurance is calculated to be better than 25 minutes. The lack of gyroscopic effect requires raising RPM to 7100 to barely maintain control; near the end of the video, the Li-Ion battery voltage sag destabilizes the gyroscopic effect even though the battery is not fully discharged. And actual endurance is 21 minutes.

The slanted Clark-Y airfoil, pictured on the right, also suffers from the complex correlation between drag and lift of the twisted Sokolov airfoil. But what makes Clark-Y worse is that it is heavier than the straight, symmetrical prototype build. The advantage of the peak of the optimization curve by reduced blade and motor weights is largely canceled. In the picture on the right, you can see a flat surface of the blade root area, giving a fixed, designated angle of attack of the blade when the flat surface is level. At 3500 RPM, the 77 throttle (collective pitch) point is lower than needed to give the designated angle of attack. About 90 throttle points to make the flat surface level. And yet, the RPM is still low on giving adequate gyroscopic effect. And, when RPM is raised, and the angle of attack lowered further, motor overheating occurs because the Clark-Y airfoil has a larger drag than the operating drag when the angle of attack is lower than the designated angle.

Tungsten or uranium heavy material blades are the solution for the curved Sokolov airfoil. The craft becomes a flying knife for military strike weaponry, not a commercial million-unit deployment.

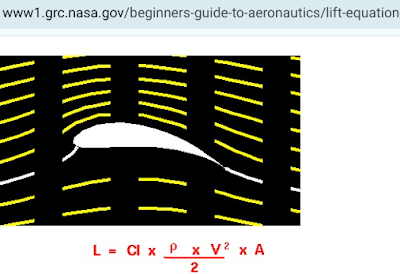

The only option left is the straight symmetrical airfoil. According to the NASA education page, the lift equation is as pictured on the right. A is the airfoil area, V is the airspeed, rho is air density, and Cl is the lift coefficient. Division by 2 should be discarded because our propeller has 2 blades that doubles the lift. Air density is about 1.2 kg/m^3, V changes linearly with x position of the propeller origin from the main shaft axis with constant RPM 2640, angular speed 2640*2*pi/60 rad/s. Area da is 0.018 blade width multiplied by dx. So, the integration is for the quadratic of x from the axis origin to the blade tip at 0.236 m. The simple polynomial integration solution is the 3rd power of x multiplied by a third of the constant. To generate 249 grams of lift, the lift force equals 2.44 newtons. And according to the dashed curve, the theoretical lift is much higher than 2.44 newtons. The section of the blade from the axis to 127 mm out should be considered zero-lifting because the hub and bolts are not part of the airfoil out to 50 mm. And between 50 mm to 127 mm, Reynold's number is too low to produce lift, which can be felt as zero downwash when tethered hover in hand. Between 200 mm to 236 mm, the blade is blown downward with the wingtip vortex of the previous sweeping of the blades. The green curve is the corrected curve. The wing section between 200 mm to 236 mm from the origin axis out is considered non-lifting. At the integration point of 200 mm, 0.2 m, the total lift is the target of 2.44 newtons.The calculation points to the solution of improving the fuel efficiency by a winglet to block vortex turbulence. However, as tried in crafting the ballasts for a 12-inch twisted Sokolov airfoil, any substantial winglet can only be safely made as an original factory part, not as an after-market modification.

The overall compound power-tran efficiency has 2 peaks with some systems, as shown in the video from SiieeFPV channel, and we use the first peaks of motor-propeller combinations for the highest efficiency (more than double the fuel efficiency). The second hump may be a motor construction oddity. It is often absent in many motors, as seen in previous plots, and may not have a mathematical interpretation.

The only solution for the endurance peak of 36 minutes is to use a 2806 motor running at 3300 RPM (according to manufacturer data tables) with straight blades to simulate an 11.5-inch twisted Sokolov setup's RPM and torque (the purple curves in the second graph of this section). And 180 mm blades approach the equivalent Sokolov propellers ((180mm*2+52)*0.7159/25.4=11.6 inch), but will have similar angular momentum with 13.3 gram blades as the prototype build. The prototype build has an angular angular momentum of 1/12 x (14.6+5)/1000 x 0.473^2 x 2640/60*6.28 = 0.101, and the solution will have 1/12 x (13.3 + 5)/1000 x 0.410^2 x 3300/60*6.28 = 0.089.

Lowering RPM And Maintaining An Elevated Collective Pitch

The well-known rotor dynamics (not just for helicopters) say that forward movement enhances lift. RPM needs to be lowered for the endurance missions to maintain the cruising blade attack angle at or higher than the optimal in-place hovering attack angle, avoiding the low efficiency of the lower attack angle.

In the following two videos with substitute Oxy2 193mm blades, called prototype(II), the RPM was set at the cruising/loitering level as in the original general build, and at 15% lower. The original is on the left, and 15% lower RPM on the right.

With the original RPM set points in RF control handset, the craft paced at 15:35 with 38 points of collective pitch, equivalent to 5 degrees; with the 15% lower RPM, the craft paced at 16:20 with 42 points of collective pitch, equivalent to 6.2 degrees, the optimal in-place hovering collective pitch set by the general build note. This validates the common, well-known rotor dynamics. The endurance improved by 5.5 minutes, reaching 29 minutes, with lowered RPM. Still with the substitute Oxy2 193mm blades, the higher attack angle of 6.7 degrees, used in the 6th cycle test for the low-C battery testing section, gave even higher fuel efficiency to reach 30.1 minutes flight time in the video in the cycling test section. In essence, the general operating note's RPM setting table is meant for in-place hovering efficiency at about 5 degrees alpha of the production build blades and at about 6 degrees of alpha for substitute Oxy2 193mm blades, not for endurance travels.

A potentiameter set point tuning knob lowers the RPM set points by 5 in the prototype to the RPM 2500 regime and by about 18 from 91 to about 73 in the production build near RPM 2650 (before compensating for temperature deviation from 50°F). The knob is multiplexed into the throttle channel in the RF control, pictured here. Notice that the -6 mark compensates for the particular ESC's underclocking for -9 points (97% underclocking).

The lowest point of adjustment is -19 points. Only -17.7 of negative-19-to-positive-19 range was used in the 30.1 minutes endurance flight to reach the ((-6)-17.7)*0.978=-23.2 LCD display point 23.2*1022/1000=-23.7 set point, RPM 3270*(100-23.7)/(100-6)=2654 in the video. This is because the throttle points are subject to the scaling of 97.8% between 1022 and 1000 PWM, so calculating RPM from PWM is cumbersome, and yet missing ESC compensation. We, instead, use the set point to start our calculation. Notice, at the video's test temperature, the "normal" RPM is 3250*93/91=3321, so the RPM is lowered by (3321-2650)/3321*100%=20% .

The modification of the RF control for endurance test includes setting channel 1 curve to the CV4 of hovering-cruising curve for the racing mode, setting RPM of the racing mode to the same as the hovering-cruising mode and with temperature and ESC compensation, all as pictured above. And the endurace test is performed in the modified racing mode to eliminate the accelerametor's perturbation of the craft, which would have reduced endurance.

Battery Pack Build

From the optimized curve, our rotor diameter 410 mm is equivalent to (410/25.4)*0.7159=11.6 inch Sokolov propeller diameter. Motor+propeller weight 62.5*(11.6/13.5)**1.5=49.8 grams. Room for battery cells is calculated at 249-111-49.8=88.2 grams with prototype craft construct. The production craft construct is about 3 grams lighter, according to the prototype build note, compared to the prototype craft, excluding motor/propeller/battery. We use GensAce1100 battery cells of 87.2 grams within the budget.

Use cuticle scissors/cutter to remove old wiring of the 3S pack first. It is too hard to use a soldering iron to clean the old wiring because the heat can damage the cells, and working too fast can accidentally short-circuit.

The rotary tool cutting disk is commonly made of insulating ceramics, and we use it to cleave one cell at the concave side so the cutter does not contact the sealing side with the electrode tabs. The solder can have work-related metallurgical hardening when the ceramic cutter catches it and grinds it. You will feel the solder tough to go through, and the cutter not contacting the fiberglass board. When that happens, simply nick-pick out the silver solder from the cutter's edge. Do not cleave the cell tabs and then attempt to solder them because the cobalt alloy does not weld with other metals, even with specialty soldering fluxes such as aluminum flux.

The front taping is a scaffolding and can get in the way of the solder when performing point jobs. In the picture here, you can see that the terminal tab for the red wire is covered by tape. I experienced a small short-circuit accident when I tried to preserve the tape and maneuvered the solder into the crannies to do the soldering job with only half the tape sliver opened. The job was repeated and cleanly executed with the front tape completely removed. A new front tape was wrapped on after all soldering jobs to the tabs were completed. This battery pack was used in the 7-cycle test, which shows that the small short-circuiting did not damage the cell.

The battery ceiling plate needs the outreaching curve trimmed at the injection mold line, as pictured here, and the bottom plate needs carving out a slope for the battery to slide into the bay. Both trimmings are required. The wedge of the battery is made with the truss as a guide while inserting foam mounting blocks.

Carbon Fiber Shaft Saves Weight

It saves 4.8-(1.8-0.1)=3.1 grams.

When using this carbon fiber shaft, the Kevlar insert is 2 and a half strands. Using 3 strands resulted in too tight a fit, resulting in a bent collar after pulling out the shaft of the prototype motor, as pictured below on the right with the tilted collar. Also, 3 strands require very, very strong hands to insert the shaft.

With the production motor, the most extreme case requires 7 strands of Kevlar insert, as pictured on the right. When measured from the rotor hub bolt hole to the bottom, the carbon fiber main shaft is 3.5mm shorter than the original build's titanium shaft. In the following picture, the rotor hub bolt holes don't appear aligned, but are correctly aligned at the upper (left) bore hole on the 10 cm mark. The tape measure is concave, so the heavier titanium shaft sinks to the bottom, and the carbon fiber shaft is closer to the camera lens. The camera lens is directly above the 18cm mark, so the hub bolt-hole image is distorted in the picture.

With the production motor, the most extreme case requires 7 strands of Kevlar insert, as pictured on the right. When measured from the rotor hub bolt hole to the bottom, the carbon fiber main shaft is 3.5mm shorter than the original build's titanium shaft. In the following picture, the rotor hub bolt holes don't appear aligned, but are correctly aligned at the upper (left) bore hole on the 10 cm mark. The tape measure is concave, so the heavier titanium shaft sinks to the bottom, and the carbon fiber shaft is closer to the camera lens. The camera lens is directly above the 18cm mark, so the hub bolt-hole image is distorted in the picture.When using the production Blade Fusion 180s fuselage: The shortened main shaft is not a problem because the v950 shaft is too long and needs to be trimmed at the bottom and still has a 3mm protrusion. The carbon fiber shaft has the right length without excess protrusion.

About every 10 sales of the carbon fiber shaft has off-center bolt boring manufacturing error, as in the picture comparison here.

3.3 Volt Computing Needs A Dedicated Power Supply

The solution is the "black 3.3v" buck converter and setting the VTX radio transmission to 200 mW to keep the current below 1.3 amp and voltage above 3.2 V.

The buck converter's voltage will drop below 3.2V and shut down the VTX when using 350(500) mW radio output setting after arming the craft, and the radio output setting takes effect. There are several brands of buck converter of similar specs that don't perform at the level of 1.3A x 3.2V = 4.16 W and shuts down VTX at a lower level. The green buck converter on the right does not power on the VTX at all. The Adafruid 3.3V 1.2A buck converter can only power on the VTX in the low-power, standby state. As soon as trying to switch on the operation mode, even for the 25mW mode, the converter shuts down the power. The converter chip for the appropriate one has the same DIN packaging across different batches with different markings. The green converter products have different packaging. The black converter is verified as used by all 30-minute endurance videos in this page. The substitute is to use the 9/10V output from the flight computer board, as pictured here.

DYS Sn20a And Favorite Blheli20a ESCs Interchangeable When Using Same Software And Configuration For Main Motor

DYS ESCs are rebranded as BladeThrust; Favorite ESCs are rebranded as Lumeneir.

With the same BLHeli v14.9 motor software and startup configuration, the Favorite 20A is interchangeable with the production-build Thrust(DYS) sn20a ESC. They require the same PID gains and the same 1.25 startup power. However, when using DYS original BLHeli software version 14.9, the BladeThrust has either battery shorting (danger!) or MOSFET burnout (danger!) within a few working cycles. So, the production parts listing uses FVT.

Here's an audio recording of the same motor behavior with the same error configuration (0.5 startup power).

Correctly configured performance of the substitute Favorite ESC is verified in the extreme robotics build notes, and additional videos are here. However, the proprietary software SKYRC is not open-sourced and can change without notice, and unuseful in production.

With the lick test, when using 1.25 startup power, the motor heat buildup curve is identical between the Littlebee and the Blade Thrust 20A ESC. After 3 minutes of attitude mode in-place hovering in hot air above 100F, the "lick" test indicates the motor core is too hot to keep the tongue in it, but the temperature drops to a comfortable warm-soup level in just a few seconds; in cool air about 60F, the core is only comfortable warm-soup level, never uncomfortable to keep the tongue in it. This setting is verified at https://www.youtube.com/watch?v=dL72Br5WKHw with 3280 RPM attitude mode and 3460 RPM diving/racing.From left to right, DYS 16A, LittleBee 20A, Blade Thrust 20A.

The ESC build is modified from the original IoT build with all stranded 20AWG wires replaced with lighter solid 24AWG enameled wires to save 2 and a half grams. The solid wires have slightly larger equivalent cross section when the gauge numbers are the same, so the solid wires can have a slightly larger gauge number.

The 16 Amp BlHeli products earlier than year 2016 are not to be used because either the dampening can not be disabled or PI loop not available.

20 Amp BlHeli ESCs in the market don't have such problem. Further more, all 20 Amp and 16 Amp BlHeli (not BlHeli_s nor BlHeli_32) have the exact same weight as shown in the above weighing. Blade Thrust brand has navy blue PCB, DYS uses green, and LittleBee uses black. BlHeli_s or BlHeli_32 are not suitable because neither has the PI loop to provide constant stable RPMs.

For the tail motor, in theory, the 3S 6A ESC can save another 0.9 grams as shown in the picture on the right, but this alternative can only function properly when maneuver is small and smooth. The startup power with 3S is too weak even though the output of the 6A ESC is adequate, as the video below on the left. And this problem persists even after startup boosting is changed to maximum in the ESC's configuration.

Soldering temperature should be standard 300 degrees for ESC jobs. When accidentally dialed the temperature to 350, it resulted in melting the MOSFET components as pictured here on the left.

Interchangeable Oxy2 193mm Blades

The Align250 grips can be stretched slightly to accommodate Oxy 193 mm blades' root. The stretched grips holding the blades are considered the standard gripping strength of our production build. But when using Blade 180 (either CFX or Fusion), they need to be thinned using a Lego planning sled, as shown in the following pictures. The router's sled is made of 2 long, thin Lego bricks CA glued to the front plate of the rotary cutting tool. The Hypertough cutting bit, when installed firmly to the end of the rotary tool's chuck, incidentally makes the proper thinning. The bumps of the bricks have gaps smaller than the long sled's width, so that the cravices never catch the sled.

The Lego flat top is well known to give a height increase of about 1.5mm on top of the bumps of bricks. If the cutting bit's shank length is not proper, or if the bricks are augmented with a flat top, the cutting bit needs to be augmented.

The thin flat Lego brick that the blades are glued on can be reused after scraping the glue off.

The final assembly, as tested in the "stock rotor" video, was without the hub-grip-gap washer because a test with the stock washer proved it too tight (with tactile movement during rotation).

Production Build Must Adhere To Parts Listing For Material Properties

An experiment on the alternative Align250 carbon-fiber blades are 0.2 grams lighter than Oxy2 nylon blades, and the blade root thickness fits the aluminum Align250 grips. The Align250 aluminum grips are incompatible with Oxy2 blades due to the narrower jaw width.

An experiment on the alternative Align250 carbon-fiber blades are 0.2 grams lighter than Oxy2 nylon blades, and the blade root thickness fits the aluminum Align250 grips. The Align250 aluminum grips are incompatible with Oxy2 blades due to the narrower jaw width. In the picture below on the left, the upper blade has a pronounced sagging due to a previous experimental test with Align aluminum grip. In that experiment, the blade root was sanded thinner, which softened the material surface. A rapid pitch-up flip at 1:08 in the video below on the right caused a tail strike. Also, the test showed that generic translucent 18-lb zip ties in the tail are not strong enough and break with the tail strike. The part listing's zip tie is stronger than the generic product's nominal tensile strength of 18 lb.

The sagging and tail strike mean that the blade surface should not be sanded to force compatibility, only carved. And this also shows that the production build's Hypertough zip ties can not be replaced with generic zip ties of the same nominal specifications.

T-Motor MN4004 And MN2806 400kv Prototype And Substitute Motors - 42 And 48 Grams Respectively

To prepare the motor for gear-less direct drive, first remove the setscrew(s) of the shaft and clamp the shaft down with a wrench socket spacing beneath the motor bell until the shaft is flush with the motor's top plane. Use a 1/2-inch wrench socket with the 4004 motors. Then, CA-glue a #6 flat-head 1/2 inch machine screw as a pusher on the clamp. Clamp the shaft down the second time with the push rod assembly, as shown in the picture, to remove the stock shaft of the motor. The main shaft is not pressure-fit to the motor but slightly thinner than the original motor shaft. The video here shows that the short bell shaft hole amplifies the thinned diameter, resulting in wobbling.

Interchangeable Microheli 180mm Blades With NACA0012 Airfoil

A pair weighs between 13.4g to 13.6g. Worst case 13.6g. Endurance of 30+ minutes verified here.

Endurance of the substitute Oxy2 193mm blades is shown in the first section discussion of helicopter gyroscopic physics, which has nearly identical endurance for builds with 180mm blades, as shown in the video discussion of Joukowsky 10.5 airfoil of the Converged IoT chapter, as well as the video on the right with interchangeable NACA0012 blades.

Tail Weight Reduction Alternatives

The original Lynx Blade 230 tail boom is 255 mm long. The replacement 8x7x500mm carbon fiber tube from ebay xzw791 can produce 2 250mm booms. The weight of the replacement is expected to be 4.8g x 250mm / 255mm = 4.7 grams. But the actual weighing has 17.6g / 4 = 4.4 grams. So, the replacement has 0.4 grams weight reduction.

Countless verification shows no differences in properties.

Motor Stator Rotation Stopper M3 Setscrew 3-5 mm All Interchangeable

|  |

.jpg)

.jpg)

No comments:

Post a Comment