Carbon Nanotube And Kevlar Interchangeable For Main Motor Friction Clutch Shaft Setup

| Prototype | Production | |

| Part | T-Motor or Sunnysky 4004 | MAD Components 2806 |

| Component | Bell Setscrew Or Kevlar Inserts | Kevlar Inserts |

| Working Mode | More Power Than High Fuel Economy Setup | High Fuel Economy |

| Failure Mode | No Failure Possible With Strong Tightening | Slip Clutch Absorbing Crash Energy With Shaft Sliding |

To prepare the motor for gearless direct drive, remove the C-clip of the shaft to remove the bell and clamp the shaft up with a wrench socket spacing above the motor bell until the shaft's bottom is flush with the bell bore's bottom plane. Use the broad open side, not the narrow ratchet shank side, because the collar of the shaft can be jammed in the ratchet's shank hole.

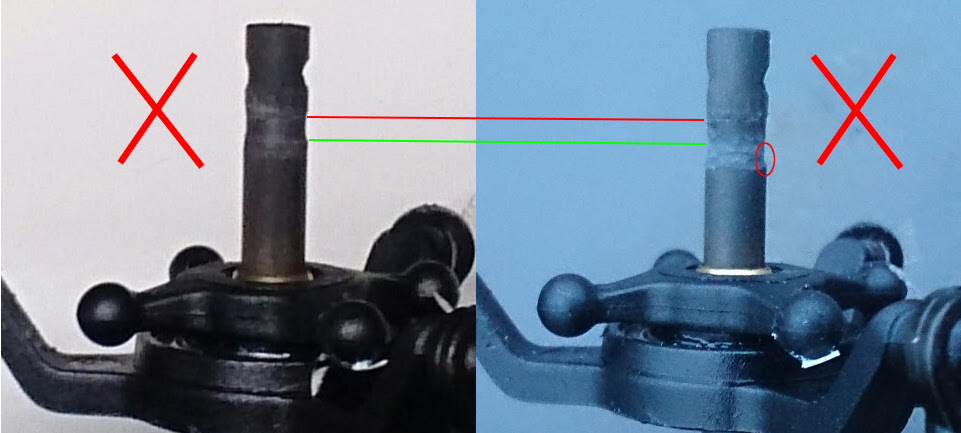

The socket spacer's orientation in the middle picture is incorrect and can catch the shaft by the ratchet attachment square borehole. The 4mm-diameter shaft itself can go through the square borehole, but the shaft has a toothed groove wider than the shaft's diameter that will jam.

The production build uses multiple Kevlar threads (dental floss) as an insert. The torque is 4.5 N · cm for a 250-gram craft lift according to MAD Component specs, likely 8 N · cm during climbing. The motor radius is 1.75 cm, so the friction force needs to be 8/1.75/9.8=0.46kg=1 lb at the motor edge.

A force gauge is not required for building. Instead, use sensation to gauge whether the force is sufficient. It should feel like pinching and holding a one-pound bag of frozen vegetables by the corner of the bag in the supermarket.

The Kevlar material can be cut by the sharp edges of the bell shaft hole and the shaft itself. So, the rim of the shaft needs very subtle, delicate scraping. The MAD motor already has a 45-degree opening of the shaft borehole, but they need to be polished, and the burs still cut the Kevlar strand, so the scraping needs to be done twice on both the top rim and the lower rim of the 45-degree slope.

The production build uses multiple Kevlar threads (dental floss) as an insert. The torque is 4.5 N · cm for a 250-gram craft lift according to MAD Component specs, likely 8 N · cm during climbing. The motor radius is 1.75 cm, so the friction force needs to be 8/1.75/9.8=0.46kg=1 lb at the motor edge.

A force gauge is not required for building. Instead, use sensation to gauge whether the force is sufficient. It should feel like pinching and holding a one-pound bag of frozen vegetables by the corner of the bag in the supermarket.

The Kevlar material can be cut by the sharp edges of the bell shaft hole and the shaft itself. So, the rim of the shaft needs very subtle, delicate scraping. The MAD motor already has a 45-degree opening of the shaft borehole, but they need to be polished, and the burs still cut the Kevlar strand, so the scraping needs to be done twice on both the top rim and the lower rim of the 45-degree slope.

The last picture above on the right shows 3/4 of Kevlar filaments severed without rounded work surfaces with the prototype 4004 motor. The Kevlar string had to be tied to form a loose loop that avoids the sharp edges of any setscrew holes inside the bell bore hole of a prototype motor bell. For the production build with friction-only fitting, there are no set screw holes to worry about, but the friction-only fitting requires multiple trials of different number of strands of Kevlar to achieve the desired friction.

Healthy hands with normal good strength are required to build it. Test insert the shaft outside the craft as pictured here. In this particular example of the production build motor, 3 strands of Kevlar were correct for the consistent, substantial friction when the main shaft is driven into the motor bell.

For a prototype 4004 400kv motor, one and a half strands of the insert were the solution for the titanium shaft with friction-only production installation for the particular batch of shafts I received. With that batch of motors and shafts, it had been tested with 2 strands of Keclar with different arrangement angles, as pictured with a green cross-out, to find them either too tight for even strong hands to insert the shaft, or Kevlar severed during the shaft insertion. Splitting the Kevlar string, as pictured below, is not hard because the fibers are held with wax.

For a different batch of shafts, however, 2 full strands of Kevlar were the right fit, and the pullout of the shaft showed largely intact 2 strands, as shown in the pictures below. So, products have a slight margin of error. It is not the more, the better when it comes to the inserts because the pull force is exerted on the motor bearing during maintenance removal of the the shaft. Too much friction can damage the bearing because there is no axial bearing, only radial bearings that can't handle too much axial force.

Before actually installing the motor into the craft, trim the shaft at the lower bore hole. The M3 set screw should be installed and CA glued half in and half out of the motor base plate as the torque point of the motor. This torque point is to be wedged in the aft section of the servo-holding truss.

The bottom retaining borehole of the shaft with sharp fixture hole edges is trimmed from the hole down, and then the shaft needs to be ground to a tapered smooth surface. There is plenty of length of the rod after the trimming, and it was accidentally discovered that the tapering needs to be prominent to guide the Kevlar strands without cutting them when I inserted the wrong end with very prominent tapering into the motor bell. The direction of the grinding sanding is to grind from the bottom of the shaft up so that any burs don't cut Kevlar. To install the shaft, use both hands to clamp. It has intense friction and only healthy hands with good strength can do it. It can be verified that the insert is unbroken after driving in the shaft and the string still retains the looping, as pictured below. Cut Kevlar is pictured on the right with a red cross. When the grinding is smooth but the tapered slope is minimal, as in the picture below on the left, it cuts Kevlar about 2 out of every 3 tries. The correct solution is on the right with a 2 mm taper slope as well as a polished edge, which cuts Kevlar less than half of tries.

The bottom retaining borehole of the shaft with sharp fixture hole edges is trimmed from the hole down, and then the shaft needs to be ground to a tapered smooth surface. There is plenty of length of the rod after the trimming, and it was accidentally discovered that the tapering needs to be prominent to guide the Kevlar strands without cutting them when I inserted the wrong end with very prominent tapering into the motor bell. The direction of the grinding sanding is to grind from the bottom of the shaft up so that any burs don't cut Kevlar. To install the shaft, use both hands to clamp. It has intense friction and only healthy hands with good strength can do it. It can be verified that the insert is unbroken after driving in the shaft and the string still retains the looping, as pictured below. Cut Kevlar is pictured on the right with a red cross. When the grinding is smooth but the tapered slope is minimal, as in the picture below on the left, it cuts Kevlar about 2 out of every 3 tries. The correct solution is on the right with a 2 mm taper slope as well as a polished edge, which cuts Kevlar less than half of tries.What happens if half a Kevlar thread fewer than optimal is used? My test resulted in a slipped shaft during rapid climb that raised the shaft by 5 mm midair. So the craft lost lift, and I applied full collective pitch for the craft to minimize the negative collective pitch, which resulted in a autorotation emergency landing. This means that the pre-install test insertions to determine the number of Kevlar strands to insert , as mentioned earlier in this section, is crutial for the success.

Sticky motor bells can occur when the clamping by hand is too strong and harsh, or it can be due to shorted motor terminals by the PWM frequency off option of the ESC or just the ESC's unmodifiable programming, as discussed in the video linked by the right picture. If not carefully monitored, clamping too firmly is common in friction fitting. The motors are rated at 1 kg lift, so there is no thrust/axial bearing. Strong hands can easily clamp at 100kg, such as in bar exercises and chin-ups. When it occurs, it has the same sticky feel as the ESC shorted terminal feel when turning the main rotor with fingers. Just pull out the shaft a bit to loosen it up.

Kevlar insert installation process cuts the material less than half of the time. So, each installation takes 1 or 2 tries. Carbon nanotube inserts reduce the failure rate by about half because they are notoriously hard to cut and trim, but delivery has a lead time of at least 1 week in addition to shipping time. In the video on the right, a 5-yard sample is purchased from Dexmat for about 20-30 USD. The carbon nanotube threads are so thin and slippery and slip in between the scissoring blades, even when the thread is under good tension. It took strong tension and repeated scissoring, about 10 times, to fully sever it. The same pair of office scissors cut clean Kevlar strings with single scissoring every time without exception. This Dexmat product is more slippery than anything ordinary people can experience.

Carbon nanotubes require the same cleaning of the work surface as Kevlar inserts. In the picture below on the left with 50 tows (filaments), the lower shaft bore hole's sharp edge severed the threads. The test to determine the required number of insert strands is the same as the Kevlar insert. In the particular motor bell, 50 tows were too loose, and 80 tows were too tight.

The solution to the fraying and hard to cut problems is to tape the ends and trim the tape to form a thin spear as the following picture. 8 strands with carbon fiber shaft, however, is the bare minimum that works in the following video.

The solution to the fraying and hard to cut problems is to tape the ends and trim the tape to form a thin spear as the following picture. 8 strands with carbon fiber shaft, however, is the bare minimum that works in the following video.Single Picoblade Connection Is Enough For Electrical Setup

| Prototype | Production | |

| Part | CC3D Atom | HGLRC F722 Zeus Mini |

| Component | Needs a 5-V power supply | 5V power supply built-in |

| Soldering | Needs wire tapping | 5V and 10V outlets on-board |

| Wires needed | Picoblade 10cm connector set | Picoblade 10cm connector set |

During the prototype build with flight computer CC3D, for the 5-V power supply, the 1.25mm-pitch connector that came with the buck converter had a current rating of 1A, sufficient with power tapping by servos plus a Full HD camera system (either Raspberry Pi or Runcam Thumb consumes less than 0.38A or 0.28A, respectively, and an analog camera with its video transmission have 0.5A extra current). The vendors often mistakenly label the Molex Picoblade 1.25 mm-pitch connectors as JST connectors. Here, the actual trade name is used throughout this build. In the following video, the current is measured on the power output of the buck converter, which powers 3 servos, a 70mA CC3D flight computer, and the 30mA 2.4GHz RF receiver.

When the servos were idle, the specification said each servo consumed 15mA, and indeed, the current reading was 145mA, with the flight computer consuming 70mA and the receiver consuming 30mA, 70+30+15*3=145. During bursts of heavy loading of servos, the reading is slightly higher than 250mA, averaging no more than 250mA. So, the servos need a 250-(70+30)=150 mA budget on 5V.

For the production build, the Picoblade connection is on a 10+V power supply of the flight computer directly from the battery, so the accessory wire with the flight computer is always safe with a more than doubled voltage and half the current. Pictured here is the female half of the 10-cm set for flight computer power tapping over the battery of 10+V; the male half is for the RF control receiver. These are the same PicoBlade connector wires for the prototype build.

The production flight computer taps power directly from the battery terminal at the main ESC as pictured here. This is designed so that no desoldering of the original factory ESC soldering work. This solves heat damages of soldering in prototype builds of other designs.

The ESCs need to be naked for maximum cooling. Without this maximum cooling, ESCs overheat in summer as shown in the video below on the right. For both the prototype and production builds, to start the dual ESC build, remove the original wraps using cuticle scissors to open them from the sides of the ESC circuit board before assembly. When tying a knot, make 2 same-orientation ties first because the 2 same-orientation loops allow adjusting length with slip. A 3rd loop should be a reverse orientation to lock the length, and then a 4th knot reverses the orientation again to double-secure the tie. The Kevlar string should snag the ESC by the electronic components. In the right picture, 2cm x 2mm clear mounting tapes sandwich the 3 solder points.

Power GPS With Flight Computer USB Port For "Warm-Up"

GPS is well-known to need a few minutes "quiet time" to synchronize with many satellites. The RF control receiver is most often tapped into the USB port for "warm-up" power, so we twist together control RX and the GPS's power leads before soldering them to the RX power pads, diagramed below. This USB-tapped power supply was meant for powering control RXs that also transmit data, but we will not use such a feature of our control RX, so this tapped power is not overdrained after the GPS is tapped.

The wires are threaded through the fixture bore holes, 2 holes per wire, to prevent tugging the solder pads during crash or during handling.

The 3-pin 10cm PicoBlade wire set male half for the control RF receiver; female half for powering the flight computer itself.

The flight computer comes in 2 versions of different port wiring assignments, and sellers don't know which version they sell. Above pictures are the 6-pin version, which has 6 lead pads in the second row at the USB port edge. The below are pictures of the 4-pin version, which has 4 lead pads in the second row at the USB port edge. The soldering points are identical except for the S5 LED (the flight computer is meant for quadcopters with 4 signal wires, but we use the LED pad for main motor control as the 5th signal) signal wire, which is marked with a green check for correct soldering. The white wire for the 5th signal is taken from the scrap of a GPS module wire. White means signal is transmitted from the flight computer.

The picture above also illustrates the wrong GPS powering with a red cross. It taps the power pads of what the manufacturer recommends for GPS powering, which does not allow "warm-up" powering with USB.

The servos tap the original analog VTX (which we don't use) 5V power with a pair of 1A 8cm wires.

Original M1-M4 signal socket faces rearward in our craft, and signal wires point out and rearward for accessible soldering jobs. The socket of the array of pins provides an even mounting surface.

The battery power tapping points for the flight computer itself are on the lower left side of the boom, stuck to the clear mounting tape (alien tape).

The servo power and main motor signal tapping points are on the right side of the boom. The servo power wires should not be twisted together because twisted solder makes replacing wires hard.

The positive and negative junctions are naked and only separated by spacing in the above pictures, but can be sealed similarly to the S1-S4 signal soldering points.

Rotor Hub Needs Bolting-In; DFC Bushing Needs Axle Insert

Nonviable screw-on retainer design not to be used: Because the loose screw retainer results in the following crash video. The punch-up was unusually weakened, the shaft was free-spinning in the rotor hub's hub when the dive had a sudden elevator-down, indicating the hub shifted.

After the crash with the screw-on retainer, the hub is found to be free-rotating, and the shaft has been ground thinner by the retainer screws. The following picture's green line is the original retainer screw's position. The red line marks the new elevation of the retainer screws after the crash.

Nonviable screw retainers design not to be used: The repairing requires that the shaft be evenly thinned around the fault point as shown in red circle in above picture so that the retainer screws will not slips to the thinned area by previous damages. Failure to smooth out the repair surface results in more slips and failures in the following video.The prototype build had frequent fuselage breaks, requiring rebuild and leaving the main shaft intact; the production build's strong fuselage can not break in all crashes and instead allows infrequent main shaft bending to absorb energy. The servo sequence of the production build is marked in the picture here.

The prototype build had long 210mm blades, and to eliminate tail strikes, the rotor is raised from the Fusion 180 fuselage's original positioning to match the prototype's proven safe clearance. The acrylic riser sheet is CA corner-bonded to the anti-rotation bracket. The height from the upper edge of the upper bearing block to the hub bolting hole axis shall be 30mm to prevent a tail strike during forceful maneuvering and crashes. As pictured below on the left, for the 30 mm height rotor setup, the shaft dent of the V950 shaft coincides with the upper bearing block, and the collar's screw wedges to the dent's upper corner in the picture after installing the collar. When friction-fitting the main shaft, the retaining collar's bolting needs dents because the extra friction used to fit the main shaft above the friction resistance can be greater than an undented collar bolting's friction can handle. More importantly, during the pull-out of the main shaft, the entire main shaft friction on the motor bell is countered by pulling the collar with a pair of pliers, as pictured on the right. The stator rotation stopper is an M3 setscrew CA-glued and bolted on halfway. Be careful not to wedge the bolt in between the strut for the fuselage and the strut for the servo because that space is not enough for free-vertical pressing of the stater onto the bearing block. The bolt should be between the 2 struts toward the two sides of the fuselage plates.

The DFC pin requires a bushing section without threads with the DFC arm. Factory partial threaded M2-15mm bolts with 3mm end threading take multiple weeks to deliver, and even then, the non-threaded section isn't a high-quality fit because a bolt is never meant to be a bushing axile. For fast production, use copper tape of 1/4 inch to wrap the section in contact with the DFC arm bushing. The copper foil tape and M2 fully-threaded bolts are part of the essential supplies of the science and art industries, so the delivery is the fastest among all parts of the build. As pictured here, the 1/4 inch copper tapes generally have a similar thickness of a thin clear station tape. The example needs 2 layers of the tape, so the length to use is 2mm x 3.14 x 2, about 12 mm. The product description of the copper foil tape often indicates "double-sided" adhesion, but, depending on the product picture, the adhesive is double-sided while the copper foil facing outside can not be double-sided with adhesives, so the outside face is without adhesives and with low friction. The wrapping doesn't need to be very neat or tight initially, but start the wrapping with correct orientation allows compacting it into the thread groove with fingernails while the bolt makes unscrewing turns. The fingernails will compact the foil in the mid section where the insertion of the bolt into the DFC bore hole start when fingernails slide off the foil. When the insertion starts, knead the foil while screwing in the bolt.

The DFC arm can swing by itself when held and released, as shown in the video above on the right, after kneading hard enough. It is vitally important that, after the installation and after a few missions, the DFC arms rotate freely and fall for at least 30 degrees. Stuck DFC results in mast bumping in the following video comparison table. The stuck DFC arm was a result of the natural tendency to self-tighten due to washer expansion with exposure to air after installation.

The DFC arm can swing by itself when held and released, as shown in the video above on the right, after kneading hard enough. It is vitally important that, after the installation and after a few missions, the DFC arms rotate freely and fall for at least 30 degrees. Stuck DFC results in mast bumping in the following video comparison table. The stuck DFC arm was a result of the natural tendency to self-tighten due to washer expansion with exposure to air after installation.

| Stuck DFC | Free DFC |

| Raw video Post-stabilization can not fix the mechanical problem | Immediately after freeing the DFC without any other changes Post-stabilization results in smooth dive |

Trim the Align 300x feathering shaft 2.5 mm from each end, which allows zero slop in centering the feathering shaft to the rotor hub while giving zero rubber friction on the grips by feel when turning them by hand. The shaft becomes 33 mm long when trimming 2.5 mm from each end, as pictured here. However, due to the lack of a flat washer between the feathering shat bolts and the shaft itself, the curved bolt head joint stops the bolting just shy of 33 mm. So, the feathering shaft will be considered 33.1 mm for discussion purposes.

The DFC bolting needs 3 layers of 1 mm nylon washers plus 1 layer of quarter mm metal washer to compensate for gyroscopic 90 degree precession. The quarter mm metal washer is not visible, but it is there. The quarter mm metal washer is taken from the Align 250 grip kit.

|  |

The trimming needs to be conservative to prevent compressing the eathering shaft dampener, as the endurance build investigated compressed dampeners and found that it was detrimental to flight characteristics. The assembled rotor is pictured here, which shows the previously invisible metal washer. The Align 250 Sport grips are concaved by a quarter mm on the grommet-facing side, which hides the grommet from view after the assembly.

Also shown in the picture are 2 strands of Kevlar dental fluss insert for each lower swash ball link and 1 strand for each upper swash ball link for the particular batch of parts received. Another batch of parts can not have these inserts with tight ball links.

The zero slop setup was verified here in the video below; 0.2 mm total slop was verified by the endurance build that showed no imbalance of the rotor.

However, when the slop is larger than 0.5 mm, the rotor is frequently out of balance with a rumbling noise. The correction is to insert a clipped C washer of M2.5 in the pictures below on the left.

The above example's conservative trimming started out as pictured above in the middle, about 34 mm, and then 45 degree grinding to 33.5 mm off camera. Then two C washers of 0.13 mm each (the thickness of aluminium soda can wall) were added after installing the grips, shortening the effective shaft length to about 33.24 mm and zero slop. The batch of hubs is 0.24 mm wider than the specification. The brand new bearings of OMP M1 are the replacement for the old bearings of the Align 250 Sport grips. The verification video, immediately after the installation, is a very windy test, here. The wind is no excuse for tremors that are faster than PID vibrations because many other windy tests don't have the tremor.

The tremors resolved by themselves for the dive punch-out 0:12 to 0:17 after three additional break-in missions. The 5th mission was without the tremors in the video below, 2 serial numbers used per mission. Serial numbers S0014 through S0019 were windless tests.

The main shaft anti-rotation setscrew is in the aft truss wedge. Additionally 1 and 3/4 zip tie insert is on the left side of the forward truss wedge. The zip tie insert should be short so not to allow it to be bent during insertion with pliers and nicking the motor stater. See pictures here.

The shaft collar bolting torque can not be too forceful with the thin and low profile bolt. Instead, the collar is designed to wedge the bolt into the shaft with wear and use and doesn't loose the grip for the lifetime of the shaft until the shaft fails and bent. See picture here.

Replacing main shaft also prompts replacing main shaft bearings (4 x 7 x 2 mm) but doesn't require opening the fuselage. The aluminum block serves as the pivot point for cantilever action to extract the bearings. The plier cantilever pivot goes in on the bearing block from the left side of the craft when extracting the bearings, both the top and bottom. However, the pliers need to have sharp teeth for the bottom bearing due to extra obstruction limiting on rotating angle. Old pliers need to try going in from both left and right side of craft.

All 1303.5 Through 1106 Motors Near 2500KV Interchangeable For Tail

| Prototype | Production | |

| Part | Gemfan 4025 straight edge | HQ Prop 4025 slanted edge |

| Component | 081.5A gear spacer CA glued | M2 bolting |

| Weight | 1.5 + 0.1 grams spacer | 1.5 + 0.3 grams bolts |

Our production build is based on improving on the prototype's glued tail propeller, which was 0.2 grams lighter. The prototype setup is pictured below. The video on the right shows the prototype's tail failure due to the slip of propeller glue adhesion, which goes into a left-turn tailspin at 2:00 and continues until the crash. There was no crash in the 11 minutes between 18:32 and 18:43 . The prop slip is distinguished from the radio loss free fall video in the Failsafe Setup section by a characteristic left turn instead of a right turn with an initial jerk due to Failsafe's sudden zero-collective-pitch setup.

We need 2 nylon washers as spacers to give room to the protrusion of the motor shaft. As shown in the picture here, the space is tight between the shaft and the tail fin board. It is OK to mill a slight concave of the fin plate at the tight spot, but we shouldn't drill a hole through because that would weaken the fin structure.

We need 2 nylon washers as spacers to give room to the protrusion of the motor shaft. As shown in the picture here, the space is tight between the shaft and the tail fin board. It is OK to mill a slight concave of the fin plate at the tight spot, but we shouldn't drill a hole through because that would weaken the fin structure. Depending on the bolt length and fin plate thickness, we can use another 2 nylon washers to cushion between the brittle acrylic and the hard M2 screws' head, and also to stop the bolting from crushing the stater winding. The motor's 2400-2750 KV range requires Y termination of the motor stater's wiring, so it is normal to see a solder stub as circled out green in the picture.

Use rotary 1mm drill to make 2 adjacent holes on the 4 corners of the attachment square for the zip ties, then break the 2 holes to form a oblong whole. Use CA glue sipping between the fin and the carbon tube.

Over tightening the tail motor bolts and/or the fin zip tie pre-load the fin with stress, resulting in premature break of the fin , as shown in the picture.

The acrylic/polycarbonate material is well known to be welded by CA glue after the cracking and be as good as new. As shown in the picture on the right, the craft was subjected to another crash that broke the tail fin again. If you look closely at the new crack, you can see the previous CA welded crack line survived the new crash and is 1 mm adjacent to the new crack line. The repairable property is absent in Kydex material because Kydex can crack and has cracked in tests, hence the choice of acrylic for the tail fin. Another disadvantage of other less stiff materials, like Kydex, is that the resonance frequency of the fin lies in the tail motor RPM range, resulting in amplified noise of the missions, sounding like a household lawn mower.

SParkhobby 1303.5 2500kv motor verified in endurance build test of "black" 3.3V power supply and extraneous collective pitch tests for the production cusped airfoil, as well as many videos in endurance note and parts note.

Mounting Radio Receiver For Reduced Interference

Without proper spacing between main motor and radio receiver, the interference can disconnect the radio locking with Flysky XM+ when the craft is well within the expected range, resulting in "Failsafe Mode free fall", when the receiver was mounted on the rear pedestal of the main frame. The spacing is sufficient about 3 inches behind the pedestal. If the receiver is further extended to the rear, the receiver is struck and destroyed by tail strike in a crash, as occurred multiple times on the 2 tail booms pictured here.

, and the 3rd case,

. In the last picture of the 3rd case, the tail strike also detached the receiver's antenna but no damages, which means that the mounting tape should be placed as far as the last picture's, at 85mm or less from the front end of the boom.

The 2 antennas of MX+ are encased by the mounting tape square.

The tail boom insert and close-up of the mounting and the option of TBS Crossfire Nano receiver follow.

Make Simple Torque Clutch For Servo Protection

To make the servo arms resilient to crash, cut the spline and partially split the arm to make a torque clutch. That way, the clutch slips whenever the impact force is larger than the gears can handle, relieving the gears from damaging forces. When dialing the spline position, loosening the arm's fastener screw is unnecessary with such a servo clutch modification.

When making the slit, do not be conservative. As shown in the picture below on the left, when one of the servos' cutting was very conservative, the clutching was overly strong, and a crash damaged the servo's internal gears. The correct way was to use the same drill bit to slit through the drilled holes as shown above, and as pictured below on the right.

The raised rotor requires raised servo arms, which are done by rotating servos to make arms on the upper side of the servos. This raises the arms by about 10mm, and then they need to be lowered by 5mm with trimming of the servo rods. Here, pictured below, the servo rod is marked with the new servo arm position, and then the original bending (2 sections) is trimmed, and a new bending is made with a plier.

The raised rotor requires raised servo arms, which are done by rotating servos to make arms on the upper side of the servos. This raises the arms by about 10mm, and then they need to be lowered by 5mm with trimming of the servo rods. Here, pictured below, the servo rod is marked with the new servo arm position, and then the original bending (2 sections) is trimmed, and a new bending is made with a plier. The trimming of the 5 mm excess needs to be conservative because of a trick we use to mitigate a bug unique to the FD411 flight computer. With the prototype fuselage build, it was discovered that when the FD411 was booted up without RF control turned on on the transmitter side, a pulse of the lowest collective pitch signal, as stipulated by the servo range configuration, was sent to the 3 servos. That made a rapid twitch down and up motion of the rotor blades, which added unwarranted wear and tear to the servos, as shown in the video on the right. But there was a solution discovered subsequently in the next paragraph.

It was accidentally discovered during the prototype flight computer installation that when the servo upper range was higher than 2080 us, the twitch motion (as in the video on the right) disappeared, which meant that the servos ignored PWM commands higher than (include) 2080 us. In the production build, the servo range direction is in inversion, so the lowest collective pitch signal pulse translates to the highest PWM signal to the servos. To ensure that the high-end signal is higher than 2080 us, the servo link rods need to be tall enough so that the high signal needs to be higher than 2080 to drag down the tall servo links. Another reason to keep the servo link long is so that the servo arms can be slightly tilted down to keep the link geometry near orthogonal when raising the collective pitch toward 6 degrees. To keep the servo link rods tall enough, the trimming of the 5mm excess needs to be conservative.

The first servo arm hole, at 8 mm, is used with the servo rods. M1.5x6mm screw (#0 American gauge screw) fastens the servo arms to the end turn, and the arm turns. Then, back off a half turn. The thread width is 1/32 inch, so half a turn allows about half a mm for servo clutch relief and ease of clutch slip. The tension can be adjusted after installing all servos with a household key ring ground to a slot turning tool. There are only 45 degrees of turning space on the aft servo, so 3 key rings are needed to make a 0, a -45, and a +45 degree slot tools.

Don't be picky about a servo's resistance in arm clutch slip. The most successful videos (most YouTube clicks) in the extreme robotics build note are shot with 3 servos with the most wildly different resistances.

Summary of the torques used in the build.

Landing Skids Of Blade 230 Series Interchangeable

The older Blade 230 landing skid has the same geometry, strength, and weight as the production build's Blade 235 landing skid.

Battery-Camera Mount

The holes on the battery tray avoid studs as pictured below. The holes for camera zip ties is 15mm from the front edge. The side zip ties require drilling of the carbon fiber side wall beneath the original bolting hole because the original bolting hole is too close to the side wall's margin.

Raspberry Pi Setup

A generic zip tie goes around the right servo and wire lead is preserved for a quarter inch on the lower part. Similarly, the battery tray's zip tie on the right aft also has the wire lead. Raspberry pi's fixture hole goes to these 2 leads.

GPS Mounting

Two 0.5 mm long Velcro hook strips are skewered by a short coffee stirring straw cut to 3.7 cm.

No comments:

Post a Comment