Interchangeable parts are not discussed. Instead, they are mentioned in the original build/operating notes.

Substitutions that reduce weight by more than 1 gram are discussed in the endurance build note. Here, the substitutes require modifications to installation or operation but are otherwise performing the same.

On-board Vision Neural Network

The Intel Movidius 2450 hardware accelerated vision neural network board in the AIY kit weighs 10.4 grams, as pictured on the right. The neural network board passes camera video through a ribbon bus pictured below on the right.

The 1.6-gram 160-degree FOV camera is incompatible with the AIY board. Instead, we need to use the 3-gram camera in the AIY kit. The weight gain is 10.4+0.1+(3.0-1.6)=11.9 grams.

The 1.6-gram 160-degree FOV camera is incompatible with the AIY board. Instead, we need to use the 3-gram camera in the AIY kit. The weight gain is 10.4+0.1+(3.0-1.6)=11.9 grams.

Install https://github.com/thecognifly/YAMSPy in Pi for the neural AI to control the travel of the craft.

Sunnysky 2806 650kv motor

It was tested with carbon nano tube insert in the above last section. No noticeable excess heat in tethered hovering. It is 0.1 g heavier than 400kv varient.

Sunnysky v4004 300kv motor - 49.2 grams

T-Motor 4004 kv400 motor - 48.1 grams

Prototype endurance build.

Prototype endurance build.

The weight of the bell is between 17.3-2.4=14.9 and 17.6-2.5=15.1 grams. The lighter blank stater(22.2g) produces a 32.2g to 32.3g stater. The weight of the stater is very close to the maximum weight of the milligram scale and can damage the milligram scale, hence the multiple weighing on the coarse scale to estimate the true weight. Worst case with the heavier bell and the 0.5g heavier stater(22.7g blank stater) is 32.3+15.1+0.5=47.9 grams. With anti-rotation nut, 48.1 grams.

The video here shows the prototype with T-Motor 4004 that used setscrew fitting in short bell shaft hole amplifying the diameter difference between the motor bell bore hole and the main shaft, resulting in wobbling in the prototype build. A single insert strand is only suitable for preventing motor wobble but cannot bond the shaft to the motor bell during operation when the bell rotates with magnetic torque force and the shaft has resistance from rotor aerodynamics.

The weight of the bell is between 17.3-2.4=14.9 and 17.6-2.5=15.1 grams. The lighter blank stater(22.2g) produces a 32.2g to 32.3g stater. The weight of the stater is very close to the maximum weight of the milligram scale and can damage the milligram scale, hence the multiple weighing on the coarse scale to estimate the true weight. Worst case with the heavier bell and the 0.5g heavier stater(22.7g blank stater) is 32.3+15.1+0.5=47.9 grams. With anti-rotation nut, 48.1 grams.

The video here shows the prototype with T-Motor 4004 that used setscrew fitting in short bell shaft hole amplifying the diameter difference between the motor bell bore hole and the main shaft, resulting in wobbling in the prototype build. A single insert strand is only suitable for preventing motor wobble but cannot bond the shaft to the motor bell during operation when the bell rotates with magnetic torque force and the shaft has resistance from rotor aerodynamics.

CC3D Flight Computer

CC3D has a helicopter graphical configuration interface, and we use its default servo sequence in the prototype builds,

CC3D has a helicopter graphical configuration interface, and we use its default servo sequence in the prototype builds,- first servo on the front

- second on the right

- the third on the left

The common alternative "3D" hobby helicopter collective pitch curve is shown as picure-in-picture here. This common alterative pitch curve can be used with F411 as well because, with betaflight, the negative pitch below the min_chedk=1385 is considered flying with a throttle cut-off. The entire CC3D configuration UAV file is downloadable here. The PIDs for rate mode have unnecessary RPM and temperature compensations for RPM3140 and cold climates, and the PIDs for tail don't have high wind resistance.

CC3D can have different PIDs for all 3 different modes, though we only utilize the switching on/off accelerameter, as illustrated in the diagram on the right in comparison to Betaflight. Betaflight has a single set of PIDs permeating all flights, and the 3 modes tuns on/off/mix the sensor/control inputs.

The actual PWM width (microsecond) side-by-side comparison as received and interpreted by the flight computer are

| FD411 | CC3D |

| (-100.0+100)/200*(2011-989)+989 = 989 ( 0.0+100)/200*(2011-989)+989 = 1500 ( 100.0+100)/200*(2011-989)+989 = 2011 | (-100.0+100)/200*(1810-174)+174 = 174 ( 0.0+100)/200*(1810-174)+174 = 992 ( 100.0+100)/200*(1810-174)+174 = 1810 |

CC3D versions higher(exclusive) than 16.09 has an alternative configuration to give stabilization precedence by arming the craft. But, we should not use it because we should not rely on transmitter disarming the craft to go into passthru-manual mode for swashplate maintenance. Remember, checking swashplate leveling is needed after each hard landing and servo arm clutch slipping/re-positioning. Also, 16.09 should be used because higher versions are underdevelopment. It is downloadable here, and it requires Windows10.

The craft is created by human and is equal to human, and it should be able to have a working mode that does not rely on human operated transmitter. The transmitter should be able to lose power at any time, and the passthru-manual mode should be fully functional. You may be tempted to workaround this problem by setting the craft to disarm itself whenever the transmitter loses signal, but this endangers the flight recovery after a brief signal loss because the disarmed craft will need re-arming midair to regain motor power, and re-arming loses the precious time in the middle of a crash landing. Humans created machines, but that doesn't mean that humans are superior to machine, and neither does it mean that machines are superior to human.

In the case of using arming to enter stabilization mode, the craft can not have swashplate maintenance once the craft has been armed after bootup; in the case of using independent aux channel to enter stabilization mode, the swashplate can be centered for checks and adjustments any time when transmitter is powered off. It is better when humans and machines can be independent of one another. And that is the setup of both the build note's betaflight dump and CC3D UAV configuration.

The terminal speed diving with CC3D with PIDs conversion for CC3D is here in the video.

The PID I term algorithm for the tail does not have a circular reset. Failsafe free fall video below at 0:03, which initially turns the craft to the right due to motor bell magnets dragging along the stater that is attached to the fuselage. Then the rewinding.

It is well known that servos accept PWM range 1ms to 2ms, or 1000us to 2000us. But, the consensus is that manufactures specify margin of error of 250us, while the signal differs less than 115us , typically below 50us, between CC3D and ESC when viewed in BLHeli configurator.

CC3D flight computer also needs 3 layers of clear mounting tape at the front and 1 layer on the back, and another temporary scaffold strip on the craft's electronics bay floor rear edge. Fold the frame edge strip inward to affirm the attachment. 1 square inch of the mounting material is enough for either CC3D or F7Nano.

There is no jig with CC3D because the CC3D Atom board is quite narrow, giving a large gap between the board and the frame wall. The first stage of the mounting only sticks the adhesive of the rear mount. Only peel off the backing of this adhesion at the first stage. The actual mounting pushes the USB plug against the inner wall of the main frame cavity while lowering the board gliding on the servo leads pressed onto the frame edge strip. The vertical strip's backing should stay on the mounting tape so that it allows slide freely until the rear mounting strip touches down on the cavity floor. The front mounting strip's backing film is not yet removed at this time, as pictured on the left. If the CC3D board is not aligned properly, abort the operation to replace the rear strip to start over. If all is aligned properly, continue on to the second stage of removing the backing film and mounting the front.

There is no jig with CC3D because the CC3D Atom board is quite narrow, giving a large gap between the board and the frame wall. The first stage of the mounting only sticks the adhesive of the rear mount. Only peel off the backing of this adhesion at the first stage. The actual mounting pushes the USB plug against the inner wall of the main frame cavity while lowering the board gliding on the servo leads pressed onto the frame edge strip. The vertical strip's backing should stay on the mounting tape so that it allows slide freely until the rear mounting strip touches down on the cavity floor. The front mounting strip's backing film is not yet removed at this time, as pictured on the left. If the CC3D board is not aligned properly, abort the operation to replace the rear strip to start over. If all is aligned properly, continue on to the second stage of removing the backing film and mounting the front.To configure the ESC, we use Omnibus F4 computer's passthrough USB-to-UART connection. And we use BLHeli configurator on Chrome browser. The configurator is not listed in chrome web store, instead, google it "chrome web store blheli" and add it. To access USB tty device, chrome needs to be restarted as root user with command "google-chrome --no-sandbox", then browse chrome://apps to start the app. Alternatively, run chrome as regular user and

# chmod 777 /dev/ttyACM0Safety precaution dictates that ESC battery power should be applied last after all connection/software are set up, and ESC battery power should be first one to be torn down after any configuration/software flashing. With that in mind, power on Omnibus computer by connecting micro USB cable, connect only the tail ESC's signal cable to a PWM out header of computer, which is on the 2nd to 5th rows. Start the app and click "Connect" with default baut rate and auto-detected tty port. The computer now goes into USB-to-UART adapter program. But, wait, there is sometimes a 1-minute delay for the program switch to occur. Now connect ESC's craft battery power, then click "Read Settings" to actually connect to the ESC computer. If the "Read Settings" button is not available, it is still in the 1-minute period. After flashing ESC, tear away ESC's craft battery power plug first, as the safety precaution. Then tear down software/other connections. If you don't tear away the power, when the program switches back to Beta Flight computer, the motor will spin up to compensate craft attitude orientation as a quadcopter motor.

And, the difference between factory uav file and operating uav file is the 3 lines of 3 servo PWM ranges, plus 1 line difference of CC3D serial number. Example,

test@galliumos:~/Downloads$ diff Converged-IoT.uav /home/test/dive.uav 4c4 < <hardware serial="000000000000000000000000" type="3c" revision="a5"/> --- > <hardware serial="54ff6b064883545328241887" revision="2" type="4"/> 20,22c20,22 < <field values="2000,1000,2000,1000,2000,2000,1000,1000,1000,1000,1000,1000" name="ChannelMax"/> < <field values="1500,1500,1500,1000,1000,1000,1000,1000,1000,1000,1000,1000" name="ChannelNeutral"/> < <field values="1000,2000,1000,1000,1000,1000,1000,1000,1000,1000,1000,1000" name="ChannelMin"/> --- > <field values="2057,1075,2000,1000,2000,2000,1000,1000,1000,1000,1000,1000" name="ChannelMax"/> > <field values="1565,1575,1500,1000,1000,1000,1000,1000,1000,1000,1000,1000" name="ChannelNeutral"/> > <field values="1057,2075,1000,1000,1000,1000,1000,1000,1000,1000,1000,1000" name="ChannelMin"/>

And the PIDs, already configured with our production Converged-IoT.uav is as the following screenshot. CC3D setting attitude mode response at 180 degrees, which is the maximum, means that full elevator stick will pitch the craft 90 degree vertical relative to the ground. Rate and acro+ modes response 1000 degrees/s is the maximum in the "Insane" responsiveness region. All those mean that CC3D has full unlimited control of the craft, and the transmitter needs to scale it down or stipulate it for human piloting, like the exponent setting in the following picture.

And the PIDs, already configured with our production Converged-IoT.uav is as the following screenshot. CC3D setting attitude mode response at 180 degrees, which is the maximum, means that full elevator stick will pitch the craft 90 degree vertical relative to the ground. Rate and acro+ modes response 1000 degrees/s is the maximum in the "Insane" responsiveness region. All those mean that CC3D has full unlimited control of the craft, and the transmitter needs to scale it down or stipulate it for human piloting, like the exponent setting in the following picture.

We have to keep the CC3D internal arming signal high during failsafe, just like betaflight.

The buck-converter-wire-to-battery-wire ties were permanent for the prototype build and should be Kevlar strings. Solder the short wires to the sides of the main ESC's battery terminals. The production build does not have an external 5-V buck converter and no such tapping.

It is OK for the short wire leads to touch the capacitor between the 2 electrical poles because the capacitor is electrically connected to the 2 poles. To save about 1 gram of weight, tail ESC build needs desoldering the original thick motor wires and replacing them with 4cm of tail motor's lead wires. The newer BLHeli_S or BLHeli_32 with protruding motor solder pads, as seen in the crossed-out in the picture, can not substitute the original BLHeli because the newer ESCs of any model have no RPM governor.

Transmitter Setup Wizard

Betaflight does not have a wizard for transmitter setup, and the throttle low limit is the same as other channel's low limit. We manually set all channels' low PWM to 989us even though they can produce 988us PWM because arming code dictates that throttle needs to be lower than the channel's low limit. In LibrePilot wizard, the Collective input value is not isolated when the wizard collects Throttle input value, resulting in a mix-up of the 2 inputs. Our production Converged-IoT.uav has the fix. It was fixed by manual entering channel numbers after wizard finished its work. The arming dictates that throttle channel needs to be no higher than, neutral level PWM, but low limit needs to be lower than neutral. Librepilot has individual channels' low limits, so, we set low limit to 0 to satisfy the second condition. And we set the neutral to 174 because the throttle output to ESC is scaled from neutral to high. In either case, setting the throttle point closest to actual TX signal's low point gives most precise RPM output.

Nonviable substitution Flywoo F745 Nano Flight Computer

The F745 Flywoo software has a custom bootup behavior, solving the "twitch" problem of generic F411 software. Due to some difficulties, the difference is persistent from version 4.2.0 through version 4.2.5,. The source code of 4.2.5 may show the branching between F411 and F745 of the difficulties.

When fixating the wires, avoid anchoring into the crevasses between the components because the stiff wires can easily damage the components, as illustrated in the picture above on the right. Each wire should be anchored by 2 points on the board to prevent ripping the solder pads. The first anchor is the threading through the tight exit holes. The front wholes are the second anchor for GPS and RF receiver wires. Camera, VTX, Main M1, VBAT-, and S4 wires are glued to a chip flat surface as the second anchor. VBAT+ solder pad is too close to the fixture hole for effective glue anchoring, so its wire uses one extra loop-around on the exit hole as the second anchor.

When fixating the wires, avoid anchoring into the crevasses between the components because the stiff wires can easily damage the components, as illustrated in the picture above on the right. Each wire should be anchored by 2 points on the board to prevent ripping the solder pads. The first anchor is the threading through the tight exit holes. The front wholes are the second anchor for GPS and RF receiver wires. Camera, VTX, Main M1, VBAT-, and S4 wires are glued to a chip flat surface as the second anchor. VBAT+ solder pad is too close to the fixture hole for effective glue anchoring, so its wire uses one extra loop-around on the exit hole as the second anchor.

.jpg)

As pictured on the right, each board fixture whole is capable of allowing seven 1A (26 AWG) wires through, or five 1A wires plus 3 thin servo signal wires. As pictured above, the F745 does not have the flat surface of JST 1mm socket like that in the F411 board. So the rear mount is 3 layers of the clear mounting tape perforated by the array of signal output, with an extra layer of narrow strips front and aft the array of pins. The front mount has a piece of paper to cushion the barometer hole to prevent air sealing. The rear 3 servo signal points are soldered in-place after the board is mounted.

Use the F745 software version 4.2.5 with this configuration .

The Main M1 signal wire appears inadequately short in the pictures due to the alternative fixating of the wire through the bottom side of the board. It should have been on the top side, and there is a good anchoring area on the OSD chip on the top side. Also this alternative fixating makes eight 1A wires through the fixture hole, which is exceedingly tight and a difficult work.

The second behavior difference is the accelerometer startup.

However, even with the Calibrate Accelerometer extra step, the switch-on of the accelerometer during the takeoff procedure can still frequently tip over the craft, 1 out of 5 to 10 tries, as investigated in the video above on the right. The overall difference between F411 and F745 flight computer configurations is here,

$ diff dump_all_converged_IoT_hglrc_fd411.txt dump_all_converged_IoT_flywoo_f7nano.txt

12,14c12,14 < board_name HGLRCF411 < manufacturer_id HGLR < mcu_id 002000503439510f37393937 --- > board_name FLYWOOF745NANO > manufacturer_id FLWO > mcu_id 0044002a3135510731303738 17c17 < # name: HGLRCF411 --- > # name: F7NANO ... hardware pinout differences ommitted here... 270d273 < feature SOFTSERIAL 311,312c314,319 < serial 1 64 115200 57600 0 115200 < serial 30 2048 115200 57600 0 115200 --- > serial 1 64 115200 115200 0 115200 > serial 2 2048 115200 115200 0 115200 > serial 3 0 115200 57600 0 115200 > serial 4 0 115200 57600 0 115200 > serial 5 0 115200 57600 0 115200 > serial 6 0 115200 57600 0 115200 315,318c322,325 < led 0 0,0::C:0 < led 1 0,0::C:0 < led 2 0,0::C:0 < led 3 0,0::C:0 --- > led 0 6,6::CO:8 > led 1 7,6::CO:8 > led 2 8,6::CO:8 > led 3 9,6::CO:8 548c555 < set acc_calibration = 0,0,0,1 --- > set acc_calibration = 0,0,0,0 553,554c560,561 < set mag_bustype = SPI < set mag_i2c_device = 0 --- > set mag_bustype = I2C > set mag_i2c_device = 1 557c564 < set mag_hardware = AUTO --- > set mag_hardware = NONE 560c567 | < set baro_bustype = SPI --- > set baro_bustype = I2C 562c569 < set baro_i2c_device = 0 --- > set baro_i2c_device = 1 609c616 < set blackbox_p_ratio = 32 --- > set blackbox_p_ratio = 16 909d915 < set system_hse_mhz = 8 913c919 < set cpu_overclock = 108MHZ --- > set cpu_overclock = OFF 951c957 < set dashboard_i2c_bus = 0 --- > set dashboard_i2c_bus = 1 964c970 < set flash_spi_bus = 2 --- > set flash_spi_bus = 1 970c976 < set gyro_1_spibus = 1 --- > set gyro_1_spibus = 4 973c979 < set gyro_1_sensor_align = CW0FLIP --- > set gyro_1_sensor_align = CW270 975,976c981,982 < set gyro_1_align_pitch = 1800 < set gyro_1_align_yaw = 0 --- > set gyro_1_align_pitch = 0 > set gyro_1_align_yaw = 2700 978c984 < set gyro_2_spibus = 1 --- > set gyro_2_spibus = 4 990a997,998 > set i2c4_pullup = OFF > set i2c4_overclock = ON 1006c1014 < set name = HGLRCF411 --- > set name = F7NANO |

Nonviable substitution Speedybee F405 Mini 20x20 Flight Computer

The ICM42688 gyro of the Speedybee F405 Mini requires the Betaflight notch filter to approach, but not match, the stability of BMP2700 and MPU6000 gyro of T-Motor F722 Mini and HGLRC Zeus F722 Mini/HGLRC Forward F411, respectively. The best possible video with Speedybee is here, which has frequent random bumps and twitches.

14-Pole EMAX 2808 660KV Motor

Below first 5 photos are of the same motor. The bell weighs 23.2 grams consistently. The modification to thin wire saves (30.6 + 23.2) - 52.8 = 1g. The 6th photo is of another motor. The stator weighs 52.8-23.2 = 29.6g to 28.7g with thinned lead wires, so 30.6g to 29.7g with original wires. Worst case with stator trimming 30.6 + 23.2 = 53.8 grams.

The 2808 motor stater trimming needs a combination of drills and pre-cuts in contrast to 4004 motors that only need pre-cuts. The outer ring does not need rotary cuts; the pliers bend and pull out the ring sections individually. Trimming the 2808 motor stater saves 33.2 g+0.1 g - 30.6g = 2.7 grams. The trimming of the 2808 motor stator base is mandatory so that the anti-rotation zip tie can thread through beneath the base. So, overall, this alternative motor weighs between 52.8 and 53.8 grams. Looking back at the first picture of this discussion section, Carving out the excess base, trimming out excess wires, and removing the stock shaft save 2.7 + 1.7 + 2.4 = 6.8 grams, resulting in 60.6 - 6.8 = 53.8 grams. The excess wires weigh 1.7 grams. When clamping the shaft down the second time with the push rod assembly, use a 3/8-inch wrench socket with the 2808 motor, as shown below. The 4004 motor and 2808 motor are interchangeable, providing that the 2808 motor has a 0.5mm shaft protrusion at the bottom of the motor, as opposed to the 4004 motor's 2.8mm protrusion The difference of 2.8-0.5=2.3 mm, matching the motor height difference of 21.3-19=2.3 mm.

The 2808 motor stater trimming needs a combination of drills and pre-cuts in contrast to 4004 motors that only need pre-cuts. The outer ring does not need rotary cuts; the pliers bend and pull out the ring sections individually. Trimming the 2808 motor stater saves 33.2 g+0.1 g - 30.6g = 2.7 grams. The trimming of the 2808 motor stator base is mandatory so that the anti-rotation zip tie can thread through beneath the base. So, overall, this alternative motor weighs between 52.8 and 53.8 grams. Looking back at the first picture of this discussion section, Carving out the excess base, trimming out excess wires, and removing the stock shaft save 2.7 + 1.7 + 2.4 = 6.8 grams, resulting in 60.6 - 6.8 = 53.8 grams. The excess wires weigh 1.7 grams. When clamping the shaft down the second time with the push rod assembly, use a 3/8-inch wrench socket with the 2808 motor, as shown below. The 4004 motor and 2808 motor are interchangeable, providing that the 2808 motor has a 0.5mm shaft protrusion at the bottom of the motor, as opposed to the 4004 motor's 2.8mm protrusion The difference of 2.8-0.5=2.3 mm, matching the motor height difference of 21.3-19=2.3 mm.

The 2808 motor stater trimming needs a combination of drills and pre-cuts in contrast to 4004 motors that only need pre-cuts. The outer ring does not need rotary cuts; the pliers bend and pull out the ring sections individually. Trimming the 2808 motor stater saves 33.2 g+0.1 g - 30.6g = 2.7 grams. The trimming of the 2808 motor stator base is mandatory so that the anti-rotation zip tie can thread through beneath the base. So, overall, this alternative motor weighs between 52.8 and 53.8 grams. Looking back at the first picture of this discussion section, Carving out the excess base, trimming out excess wires, and removing the stock shaft save 2.7 + 1.7 + 2.4 = 6.8 grams, resulting in 60.6 - 6.8 = 53.8 grams. The excess wires weigh 1.7 grams.

When clamping the shaft down the second time with the push rod assembly, use a 3/8-inch wrench socket with the 2808 motor, as shown below. The 4004 motor and 2808 motor are interchangeable, providing that the 2808 motor has a 0.5mm shaft protrusion at the bottom of the motor, as opposed to the 4004 motor's 2.8mm protrusion The difference of 2.8-0.5=2.3 mm, matching the motor height difference of 21.3-19=2.3 mm.

To understand tuning RPM in BLHeli Configurator for the 14-pole 2808 motor, consider increasing RPM by 50 from 2643 to 2693; the new scaling size 981, which produces 50000.0 / 7.0 * 74.0 / 200.0 * 1000.0 / 981.4 = 2693 RPM. So, a 19 PWM change produces a 50 RPM change, a 1 to 2.5 ratio. Also, with the small diameter of the 2808 motor with smaller torque, the fail-safe test video on the right successfully recovered RF control loss with a 2808 motor using ESC governor p-gain 0.5, the same value as the 4004 motor's high punching power setup.

Main motor ESC

Tail Motor Alternatives

To understand tuning RPM in BLHeli Configurator for the 14-pole 2808 motor, consider increasing RPM by 50 from 2643 to 2693; the new scaling size 981, which produces 50000.0 / 7.0 * 74.0 / 200.0 * 1000.0 / 981.4 = 2693 RPM. So, a 19 PWM change produces a 50 RPM change, a 1 to 2.5 ratio. Also, with the small diameter of the 2808 motor with smaller torque, the fail-safe test video on the right successfully recovered RF control loss with a 2808 motor using ESC governor p-gain 0.5, the same value as the 4004 motor's high punching power setup.

Main motor ESC

Tail Motor Alternatives

Align300x Main Grips - 8.5g

They have the same arm span of 12mm as the Align250Pro's grips. They have the same radial bearing spacing and depth as Align250's. But they are longer and can accommodate a thrust bearing at the far side. Unless trimming the main blades, Align250's grip span is too short to accommodate any thrust bearing in-between or at the far side.

The Align300x grips need to be paired with Align300x's hub because the feathering shaft's width is limited to 38.5mm in the market. Overall, this alternative adds a weight of (8.5+2.45-0.3)-(6.2+1.4)=3 grams.

Tail Servos For Swashplate

To compensate the exaggerated servo travel, the servo PWM range per direction needs to be attenuated to 500us x 12mm/13mm x 83.1degree/83.3degree = 460us . The following video is with Spektrum 2070T servos on the cyclic swashplate performs with CC3D.

Two Alternative Action Cameras

Runcam Thumb 1080p's video with Gyroflow stabilization is on the right.

To use Insta360 Go, the battery is a 49-gram 4S 450mAh set up in the following pictures. The problem with Insta360 is that it has in-frame stabilization instead of open-source between-frame stabilization. In-frame stabilization looks great during the first 2 minutes of video footage but produces jello with 3140RPM and twitches with 2640RPM with timing/synchronization aliasing.

Runcam Thumb Pro - 13.2 grams. The camera weighs 16.485g. Removing the lens protector saves 1.550g; removing the lens protector and back cover saves 3.578g. The set includes a 4-pin PicoBlade connector with cable, but we only need 2 pins with 8cm cables, as weighed in the PicoBlade section as 0.3g. 16.485g - 3.578g + 0.3g = 13.2g .

As pictured, this dive also uses a dedicated battery pack for the full HD camera.

Ultra-light Action Camera Substitute

In addition to the prototype motors, the T-Motor MN2806 400kv works, as shown in the following diving. This dive uses a 10A 1-3S DYS ESC and a carbon fiber main shaft, the same as in the endurance build. And this dive uses a brand new Align 250 Sport grip set.

Single antenna disrupted video

Remove the casing saves 11.271g. Don't use the camera itself that is (5.646+0.981+1.336) = 7.963g. 15.668 - 7.963 + 0.608 = 8.3g.

Spool-up collective pitch angle can be tuned to a smaller angle

But, wait, during spoolup, the flight mode is manual, the tail motor does not spin, so some negative collective, say -15 points, is required to produce friction between landing skid and the ground to prevent tail spinning. Remember, zero collective pitch doesn't mean zero torque.

Also, if you tune it to very close to 0 points (0 degrees), say -1 point, betaflight min_check=1386 configuration needs to be raised to min_check=1500 , so that the craft can arm. Remember, whenever RF transmitter is turned on, the -23 points, or, the new -1 point, is activated. And you need to arm the craft at this -23 points or -1 points that is lower than min_check . However, if you actually set min_check to 1500, any slight touch of ANY stick toward low position triggers the stick command(s) as the first picture below because min_check applies to all sticks.

One possible solution for allowing near-zero-collective-pitch-spoolup is to enable computer stabilization during spoolup and disable stick functions all together. But disabling stick functions requires modifying source code of betaflight, and enabling computer stabilization on the ground defeats the purpose of the spoolup-manual mode. Another possibility is to set up the throttle channel 1 as the main motor PWM RF signal, but the flight stabilization features that are based on throttle channel 1's variation, such as "TPA" and "TPS", can not be used because the helicopter's main rotor RPM is a constant during the flight.

From safety stand point of view, the negative spoolup pitch should be as far from the stick center as possible; from the operation stand point of view, the stick should be as close to the neutral collective pitch as possible.

The only viable possibility is to physically dial up the servo clutch so that PWM 1385 is the neutral position with zero collective pitch. And such alternative needs the collective pitch curve shifted down as above second and third pictures, but still the near-zero-collective-pitch-spoolup's tail spinning problem is not solved.

It is possible to automatically disengage pilot's RPM spoolup

We can use a logical switch in the RF controller to automatically switch on the accelerameter(attitude) mode as soon as the throttle goes higher than -26 (74 out of the 200 points) of 1/4 throttle stick position. But this means that accelerameter(attitude) mode can be downgraded to manual spoolup mode during flight when throttle stick is lower than the 1/4 position. This is due to the fact that logical switches don't have direction awareness whether a craft is taking off or landing. So, pilot would end up needing to be trained to avoid lowering stick to lower than 1/4 position when the craft is in the air in attitude mode in this alternative setup, which can be difficult. One possibility is to use a manual mode throttle curve that reaches spoolup at 1/8 stick. But, still, pilots needs the extra training to avoid lowering stick to 1/8 position. And, the 1/8 position spoolup makes the stick very sensitive to the touch during spoolup.

It is possible to tune the spool-up sensitivity

The 1/4 position full spool up can be changed to 1/8 position with the 9-point throttle curve, which the rotor RPM becomes very touchy and sensitive.

False Alternative Kalman Filter

Neither HGLRC FD411 nor CC3D has the main development branch with Kalman filter. Frequency domain engineering is still the mainstay in the foreseeable future. This is a false alternative.

Five Alternative Battery Packs

650mAh is an alternative that needs alteration of the main frame, trimming out the battery bay ceiling beam, which severely weakens the crash resistance and is unsuitable for adrenaline proximity diving. The crazepony 2S batteries are lighter, 2 packs joined by the trimmed powering wires, not the charging wires.

The GNB packs are heavier and 1mm taller. And the lower jaw of the battery cage needs to be ground 45 degrees at the opening. When the back is installed into the battery compartment, the upper pack is stopped at the wall stud inside the main frame. The pack build uses 18cm of clear tape. The GNB 4S 650mAH, pictured below, does not need the grinding of the main frame.

The RDQ 525mAH, pictured on the right, has the same dimensions as GNB 520mAH but is 0.4 grams heavier.

The XT30 connector can be substituted with EC2 connectors

without adding weight, but EC2 needs clamping tools.

For the FrSky XM Plus receiver with a repairing replacement antenna,

the replacement is about 1 inch longer and it coils around the boom stick for 1 turn.

Using Servos With High I-Gain

The high I-gain of the E-Fligh S-60 slows servo response time to gain precision.

The high I-gain of the E-Fligh S-60 slows servo response time to gain precision.For terminal speed divings that need fast PID loops adjustments, the solution is to use 194% P gains in CC3D to buy time for the servo in a dedicated, special "dive mode", which should be meticulously applied before the diving or during the long dive by turning the the switch lever to the middle position. The diving with the S-60 servos is the video below. The pilot needs to be trained to flip the mode switch all the way down back to normal acro mode between 0:28 and 0:30 to produce a seamless video. Because this switching has a very small window time, the normal acro mode is set up to be at the low extreme end of the 3 position switch in the Converged-IoT.uav , so that the switching back action can be swift.

Alternatively, the video with extra 94% gain with vibrations can be edited out post-production, as the following,

The option Spektrum H2070T servo does not have the high-I-gain problem and is fully compatible with Emax 9051 servo, as shown in the video here,

High-wind FPV landing is risky.

In the above landing approach, I first tilted the head of the craft down so that I could see obstacles around the landing patch on the ground. I continued to keep the head down so that the camera points toward the ground from 0:12 to 0:22 while descending. I ended up facing wind and away from the landing patch because the wind is blowing toward the fence. I flew blindly because I was facing away from the fence and landing patch from 0:22 to 0:30 during final approach. I ripped off the FPV goggles at 0:32 to try to land line-of-sight, but I didn't have the training to fly LOS when the craft flies toward me at the landing target. I was disoriented at 0:37. It crashed.

The appropriate approach planning should be exercised to reduce the risk of landing in high wind as the following table.

The appropriate approach planning should be exercised to reduce the risk of landing in high wind as the following table.

| This is the most favorable condition. Same with landing an airplane. The head wind slows down the craft. The craft elevator tilts downward to resist the wind. At the same time, the FPV camera points toward the ground for clear view of obstacles. With crosswind, unlike an airplane, the drone does not need to change approach heading because the drone flies side ways just as fast as flying forward. So, the craft tilts side ways and forward at the same time FPV camera points toward the ground for clear view of obstacles. With tailwind, without changing approach heading, the craft needs to tilt its head up, pointing FPV camera toward the sky resulting in blind landing. If the pilot heads toward the wind to tilt the FPV camera down to see the ground, he is facing away from the landing patch flying backward blindly as seen in previous crash landing video. The solution is to change heading and convert the tailwind to cross wind. The field of view of the camera only approaches 180 degrees and less, so the side way approach needs a slight forward movement, and the craft lands slightly off the landing target. With tailwind and slight crosswind, the heading should be perpendicular to the wind and heading toward the crosswind component of the wind. The landing target is with in the field of view of the camera. The craft tilts toward the ground to resist the crosswind at the same time the FPV camera points toward the ground for clear view of obstacles. When crosswind mixed with headwind, no heading changes needed because there is no tailwind component to force the pilot to tilt the craft and the FPV camera toward the sky. This is the first and second condition combined. And not heading change needed for either component of the wind. |

Voltage Monitoring Alternatives

It can be inferred in the following video that Caddx Turtle's voltage OSD shows the voltage is floored to the nearest 0.5 volt. The 10+ second dive starts at 3:59 , and the on-board HD video here,

However, either Caddx Turtle or Runcam Split's voltage range is 10-13V. There is no 4S voltage monitoring.

However, either Caddx Turtle or Runcam Split's voltage range is 10-13V. There is no 4S voltage monitoring.

FPV And Action Camera

I have tested four different power supply configurations. First, the FPV and action camera share a buck converter, and the VTX does not have stub power tapping wires for the FPV camera; there was diagonal line noise in the FPV feed. Then the main buck converter was replaced and stub power tapping wires are added to VTX. The FPV and action camera share a buck converter. Still severe diagonal line noise in the FPV feed.

After swapping the shared buck converter, still obvious diagonal line noises.

Finally, the FPV camera used the VTX power tapping, and diagonal line noises resolved.

But wait, the TPU mount produces jello for the HD video, as shown on the right. The TPU mount is no better than just 3 zip ties in the original IoT craft build. Add a 6-8mm wide mounting tape to the front plate edge, as pictured below on the left. The double-sided mounting tape's non-stick backing should stay on the top side, contacting the camera body so that the camera can slide off for maintenance. Only peel off the backing on the bottom side bonding to the craft.

But wait, the TPU mount produces jello for the HD video, as shown on the right. The TPU mount is no better than just 3 zip ties in the original IoT craft build. Add a 6-8mm wide mounting tape to the front plate edge, as pictured below on the left. The double-sided mounting tape's non-stick backing should stay on the top side, contacting the camera body so that the camera can slide off for maintenance. Only peel off the backing on the bottom side bonding to the craft. When tying down the camera, use enameled wires, which allow some hand manipulation of the final angle, which should have a tilt to compensate for helicopter physics that needs a tilt (roll) angle for in-place hovering. Don't use Kevlar thread in this case because it is complex to navigate through the gaps of the zip ties, as shown in the following pictures. With the ThumbPro camera, use the rotary disk to cut a notch at the joint between the camera lens pole and the camera body, as pictured on the right, so the zip tie can sink in.

The TBS Unity VTX, either pro or pro32 nano, comes with 4 wires about 9cm long.

3 wires connect VTX to FPV camera, and the 4th wiretaps the battery's power to the HD action camera.

3 wires connect VTX to FPV camera, and the 4th wiretaps the battery's power to the HD action camera.The non-shielded, high-power TBS Unity Pro VTX has an oscillation problem with impedance changes on terminal points. As discussed by YouTubers and pictured below,

The solution is to bend the wiring out of the terminal points to tune the impedance, as pictured below, with the verification video on the right.

The tuning picture above on the left is the closeup of the CG Setting section's setup picture. And with the same setup, shown in the image in the CG Setting section, the sharing of the VTX power with servos is incidentally verified here not to be the source of the oscillation.

Terminal Speed Diving And High-G Pull-Up With 3-Series LiPo Battery

On pull-up, with pre-prototype build of 3S battery and diving at RPM 2607, pull-up with maximum 1666us PWM on ESC and full pitch, airfoil operates as the following diagram.

A workaround for the weak power plant is to maintain the diving collective pitch for a few seconds, after angling the craft for pull-out. as the following airfoil operation diagram.

In such a self-imposed flight-envelope, at 23 degrees effective angle of attack, the lift slows down the descent enough that the airfoil operating moves to the normal operation region, as the following video, which holds back throttle for 3 seconds at the bottom of the dive after leveling the craft to horizontal. This dive still used RPM 2607.

And with RPM 2607, I can only eliminate the swinging motion by diving with 20 degrees off the vertical line. Terminal vertical speed is 20m/s, as seen in urban diving video, which is significant to the rotor head wind speed, at 42%, 20 to 48 m/s that is calculated in build notes.

Main Shaft Collar Alternatives

EFlight BSR 0.5g; Microheli Blade 130x 0.1g

The Blade mCPX main shaft is 3mm in diameter and is not a replacement for our IoT build.

AKK IPEX 5.8GHz antenna - 1.2 grams Oxy2 Sport DFC Bolt Set - 1.2 grams

AKK IPEX 5.8GHz antenna - 1.2 grams Oxy2 Sport DFC Bolt Set - 1.2 grams

F. According to NASA's education page, an airfoil's lift is proportional to air density, which is linearly proportional to absolute temperature; an airfoil's lift is proportional to attack angle, which is first-order propotional to P gain. To fit the PID-temperature data, the temperature is given a 1.3th-order power to account for attack angle's non-purely-linear power on lift and exaggerate the PID range in the tabulation, with -9°C (264K) as the calculating temperature as in the comparison video at the beginning of this discussion section,

physical Ppitch=0.002*(tempK/268)^1.3

physical Ipitch=0.040*(tempK/268)^1.3

physical PI for roll is 1/3 of those for pitch

, and the resulting tabulation for racing PIDs on the right table.

However, even with exaggeration, the PIDs in the right table does not cover the full range of PIDs needed to compensate for the variation of the swashplate slop. For an old swashplate with many crashes, the video shows the play between the outer and inner rings of the swashplate's bearing.

The swashplate is prone to slop because the bearing is designed to bear lateral/radial forces, but crash forces can be longitudinal/axial. For example, the brass inner ring of the swash can bite into the titanium shaft during impact, and the DFC link simultaneously pushes the outer ring of the swashplate bearing upward. The swashplate and the grip bearings are the only two metal-to-metal grinding points in the rotor of this craft, but the grip has thrust bearings designed to withstand longitudinal crash forces.

When gauging the slop degradation, hold the craft vertically to drape the blades and gently tug the DFC links up and down to see the scissoring movement's end position, as pictured here, which is with the swashplate with considerable slop used in the first video of this chapter page.

Tugging up produces a 2mm gap between the front blade on the left and the hind blade on the right; tugging down produces an 8mm gap between the front blade on the right and the hind blade on the left, as pictured above.

With a brand-new swashplate, tugging up produces no gap, while tugging down produces a 3mm gap, as pictured below.

For swash centering and gauging purposes, the tuggings must make the blade tips switch places or perfectly align with a tugging direction while producing a gap with another tugging direction. The gaps need to be summed because the swashplate is not perfectly centered due to the limited precision of servos, which is 0.83 degrees, as discussed in the operating notes https://nocomputerbutphone.blogspot.com/2018/09/converted-iot-drone-operation-notes.html. In the examples, the old swash has a sum of gaps of 2+8=10mm, while the brand-new swash has 3+0=3mm. Our tabulation is for use with brand new swash plates for production builds with 193mm blades; equivalent for use with 6mm gap sum for prototype builds with 210mm blades. The loose swashplate example in the first video of this chapter page requires and uses cyclic PIDs 10-6=4 entries above the calculated values in the tabulation; the brand new swashplate of Balde 230S with 210mm blades with a 3mm gap sum requires cyclic PIDs 3-6=-3 entries below the calculated values in the tabulation. When brand-new DFC links are used with brand-new swash, the slop will be too small to gauge using the sum-and-difference method because you can't always find a swash position to make the scissoring of blades switch directions. This happens when the slop sum is smaller than 3mm - the limit of servo precision. To understand this limit, using the brand-new swash pictures as an example, the perfectly centered swash should produce (3+0)/2=1.5mm gaps either tugging up or down. The example picture shows the servos lower the blade tips by 3-1.5=1.5mm from the ideal perfect center. The servos are arcsin(1.5mm/207mm)=0.415 degrees too low. 207mm is the length of the blade's leading edge as viewed on the ruler. But adding 0.83 degrees would make the servos 0.83-0.415=0.415 degrees too high, producing a 207mm*sin(0.415)=1.5mm deviation of swash center, the same deviation as before, just a different place.

The following 2 videos show the prototype build diving with PIDs setting of the brand-new swashplate at 2.5 entries below 60°F, at the 35°F setting. The raw footage is on the left, and the post-production stabilized video is on the right.

The dump_all config file has 4 PID profiles for 0°F, 66°F, 33°F, and 100°F settings for the prototype build.

So what happens when PIDs are set from the lookup as-is without adjusting for swashplate slop? The video below on the left has 3-notches oversetting PIDs, and the shaking of the craft at 0:22 and 0:27 is unnerving to the pilot because the craft is making a smooth turn, equivalent to 0:22 of the previous video of optimal PIDs setting with 3650 RPM. In the video below on the right, the PIDs are 5 notches too high for the same brand-new swashplate, and viewers, not just the pilot, can see that the craft is shaking itself apart.

On the other hand, with the old loose swash, the lookup PIDs are 4 notches too low in the following video. The left side is the raw video, and the pilot can see shaking at 0:15-0:16 during a smooth turn. The right side is the stabilized version, and the footage sees twitches throughout the level traveling.

HD-FPV Camera

Four different powering options have been tested, similar to the FPV camera setup section of the high-performance build post https://nocomputerbutphone.blogspot.com/2018/08/converged-drone-at-edge-of-space.html.

- The MP1584 chip-based buck converters, such as the Bluesky 5V power supply, are the worst for analog video applications.

- The second worst noise interfering with FPV feed is with 12-16V direct battery power supply to the Caddx Turtle cameras (v1, v2, and Baby) in the following video; if you watch the original feed video file https://drive.google.com/file/d/1nL07CPVMDrWu_w7SFtraSYZqxUejrDJr (download it then watch it on a video player instead of watching it online with an online player because online video servers process out the noises to save their internet bandwidth).

- The FPV feed is best clear of interference lines when VTX's 5V aux power filters out low-frequency ripples. However, the market trends move away from VTX aux power and toward pass-thru powering.

- The solution is to share power with servos of the base build, the same as the high-performance build, which has a Wolfwhoop MP2315-chip-based buck converter power supply.

With an extra alternative 10uH inductor, the FPV feed has the video ripple noise level between direct battery power and VTX's aux power in this solution. The ripple noise can not be completely eliminated with a 10uH inductor LC filter because the ripple frequency is similar to or lower than the 10uH inductor working frequency. The ripple noise can not be eliminated with an electrolyte audio A/C capacitor, either, because the ripple frequency, around 1MHz, is much higher than the electrolyte capacitor's audio working frequency.

As pictured on the right, a scrap plastic strut fixture is needed to hold the camera board vertically. Use kevlar strings or enameled wires to tie the board to the strut and craft body. And then, CA glues the fixture arm.Prepare the SD card by sticking it onto a tape with a mounting square, then tear off half of the unused tape. After installing the SD card, fasten the mounting square onto the steel plate of the camera board.

Do not drill holes on the sides of the main frame wall to fasten the camera board because that will weaken the structure and damage the camera wire connectors during a crash. The experiment shows a complete cleavage of the upper main frame when the left side wall is weakened with fastening holes.

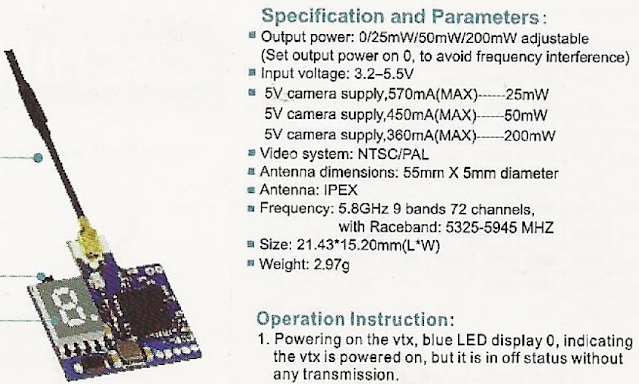

The alternative Eachine VTX03 has AUX power at 360mA, as shown in the specification on the right. It can give the best FPV feed with Caddx Baby Turtle. However, as seen in the following specification comparison, the alternative Runcam Split has a much larger power consumption than the VTX03 can support.

Runcam Split series tapping AUX power of VTX03 results in video freeze with high G maneuver power surges/dips. One incidence of such video freeze is below on the left during punching, where the drone is lost from a considerable altitude.

A second video freeze incident with Split is above the right. If you watch the video to the end, the frozen last frame stays indefinitely after the drone touches the ground.

Substitute T-Motor F722 Mini (US stock fast shipping)

Half and half of all diving videos on the extreme robotics page are with HGLRC Zeus F722 Mini and with T-Motor F722 Mini. The T-Motor flight computer is 1.4 grams heavier; the Skystar flight computer is 0.8 grams heavier than the T-Motor flight computer, still.

When using the T-Motor F722 mini flight computer, the servo power tapping and the battery power input switch sides from the production build. This is because the signal bus of the flight computer is in the mirror orientation between the T-Motor F722 and HGLRC F722, as the following picture shows. This substitute flight computer is used in many videos in this page.

When using the T-Motor F722 mini flight computer, the servo power tapping and the battery power input switch sides from the production build. This is because the signal bus of the flight computer is in the mirror orientation between the T-Motor F722 and HGLRC F722, as the following picture shows. This substitute flight computer is used in many videos in this page.Flight software https://drive.google.com/file/d/1pg7u6Lu_YTL9cSmApZCHNXqaG0uHcQiw/view?usp=drive_link

dumpall https://drive.google.com/file/d/1JKzeFYqmqPGFbU8UPpW67yoY2VoHuNzC/view?usp=drive_link

When using this substitute for scientific investigation purposes, the dump_all file differs from the production build in PID sampling rate, gyro logging rate, gyro data filtering mechanism, and GPS algorithm, as follows,

When using this substitute for scientific investigation purposes, the dump_all file differs from the production build in PID sampling rate, gyro logging rate, gyro data filtering mechanism, and GPS algorithm, as follows,

test@penguin:/mnt/chromeos/MyFiles$ diff dump_all_converged_IoT_HGLRCF722.txt dump_all_converged_IoT_TMOTORF7.txt

# pinout/timer/dma/servo center/ truncated 510c504 < set gyro_lpf1_static_hz = 0 --- > set gyro_lpf1_static_hz = 125 512c506 < set gyro_lpf2_static_hz = 188 --- > set gyro_lpf2_static_hz = 0 529c523 < set gyro_lpf1_dyn_max_hz = 0 --- > set gyro_lpf1_dyn_max_hz = 500 574c568 < set blackbox_sample_rate = 1/2 --- > set blackbox_sample_rate = 1/4 | # barometer/board/gyro orientation/ibata truncated 672c666 < set gps_ublox_flight_model = AIRBORNE_1G --- > set gps_ublox_flight_model = AIRBORNE_4G 710c704 < set pid_process_denom = 8 --- > set pid_process_denom = 1 714,715c708,709 < set simplified_gyro_filter = OFF < set simplified_gyro_filter_multiplier = 100 --- > set simplified_gyro_filter = ON > set simplified_gyro_filter_multiplier = 50 # camera control/pinio truncated test@penguin:/mnt/chromeos/MyFiles$ |

There is no difference between using lpf1 (my t-motor f722 setup) and lpf2 (my zeus f722 setup). Lpf2 filters before PID loop sampling the craft attitude; lpf1 filters after PID loop sampling, which is a Betaflight software design error. But the advantage of lpf2 is only to quash the aliasing noise frequency at the difference between gyro data sample frequency PID loop frequency. Here the t-motor f722 has no difference between the 2 frequencies - both are 8kHz.

The blackbox_sample_rate of 500 Hz in the production build is sufficient for generating fingerprints for Gyroflow to lock time-matching points.

A test with 125 Hz could not reliably make lockings of time matches. Gyroflow-smoothered video with a 500 Hz logging rate is in many videos of this page.

With the GPS connected to the same power source as the RF control receiver, the GPS power wires are twisted onto the receiver power wires.

This allows GPS to be locked before powering on the craft with the battery. It is suspected to add interference to the gyro with the added active GPS electronics in the first few seconds of booting up the flight computer, which is the time when the gyro is calibrated by software. However, the test video on the right shows no more yaw drift than the production build's GPS powering scheme.

Sunnysky 2806 Motor On Carbon Fiber Shaft (US stock fast shipping)

Then, CA glue a #6 flat-head 1/2 inch machine screw as a pusher on the clamp. Clamp the shaft up the second time with the push rod assembly, as shown in the picture, and remove the stock shaft of the motor.

It uses 3 Kevlar strand inserts for the Sunnysky 2806 motors on a worn carbon fiber shaft.

The substitute 2806 650KV motor doesn't produce noticeable excess heat compared to a 2806 400KV motor. But, as expected, a 2806 motor has noticeable extra heating compared to a 4004 motor. This 650KV was tested in the previous section's HD camera tilt-down test. When using the Sunnysky substitute motor, trim the motor stater base as mandatory for friction fitting because the servo tabs are slightly longer than the bearing block height and protrude beneath the lower bearing block. During the pull-out of a shaft, the pressure exerted on the servo tabs and tab bolts can damage them and destabilize the servos if the motor stater base is not trimmed. As in the middle picture above on the right, all the black marked lines in the weighing picture are trimming lines. All rotary cuts are pre-cuts when trimming the stater base, leaving 1mm for safety from damaging the stater winding. Then, plier bending the material causes metal fatigue that actually makes the breaks. First, to trim the motor's stater base, preserve the outer ring as a guard against accidental rotary tool slips. Any rotary tool cuts are pre-cuts that don't go through the plate. Then, 6-inch long nose pliers bend along the pre-cut edges, and metal fatigue breaks the material. Trimming the 4004 motor stater saves 36.1-34.8=1.3 grams, as pictured below of the substitute 4004-300kv motor. The 2 pictures also reveal that the 300kv motor is about 2.5 grams heavier than the 400kv motor.

The substitute 2806 650KV motor doesn't produce noticeable excess heat compared to a 2806 400KV motor. But, as expected, a 2806 motor has noticeable extra heating compared to a 4004 motor. This 650KV was tested in the previous section's HD camera tilt-down test. When using the Sunnysky substitute motor, trim the motor stater base as mandatory for friction fitting because the servo tabs are slightly longer than the bearing block height and protrude beneath the lower bearing block. During the pull-out of a shaft, the pressure exerted on the servo tabs and tab bolts can damage them and destabilize the servos if the motor stater base is not trimmed. As in the middle picture above on the right, all the black marked lines in the weighing picture are trimming lines. All rotary cuts are pre-cuts when trimming the stater base, leaving 1mm for safety from damaging the stater winding. Then, plier bending the material causes metal fatigue that actually makes the breaks. First, to trim the motor's stater base, preserve the outer ring as a guard against accidental rotary tool slips. Any rotary tool cuts are pre-cuts that don't go through the plate. Then, 6-inch long nose pliers bend along the pre-cut edges, and metal fatigue breaks the material. Trimming the 4004 motor stater saves 36.1-34.8=1.3 grams, as pictured below of the substitute 4004-300kv motor. The 2 pictures also reveal that the 300kv motor is about 2.5 grams heavier than the 400kv motor.

NACA(NASA) 0015 And 0012 Airfoil Both Capabile Of Terminal Velocity Diving Pullout

The airfoil of SP-Oxy2-081 (black graphite nylon) blades and SP-Oxy2-086 (colorful nylon) are NACA 0012 and 0015 airfoils respectively. Search "SP-OXY2-086" or "SP-OXY2-080" is most effective in finding sellers.

NACA 0012 airfoil stalls at 2 degrees earlier in attack angle as ploted here (50,000 Reynold's Number, between aqua color ncrit number 5 and soil color nrit 9).

When pulling off a terminal velocity dive, the collective pitch needs to be delayed. Do not add a collective pitch first because helicopter physics dictates that the craft pitches upward with a positive collective pitch, resulting in stalled movement with a large collective pitch in a high sinking rate. The video on the right (with Sunnysky v2806 400kv motor and 20A ESC) shows the stalled, stumbled pulloff when collective pitch was applied too soon and forceful. The NACA 0012 airfoil pull-off requires more skillful, earlier, subtler cyclic pitch-up to keep the craft borderline stalled while the stall lowers the craft; video footage below on the left. The NACA 0015 airfoil pull-off does not encounter stall by procedure; video footage below on the right.

4-series lipo is required in this procedure. The 3-series Lipo battery pulloff has a different procedure to avoid vortex ring state, discussed in the substitute parts chapter page, not on this page.

During the prototype build with the substitute camera Insta360 Go, it was discovered that moving CG forward stabilized the diving, as seen here. When using the substitute Runcam Hybrid2, which weighed the same as Insta360 but distributed weight rearward 6cm on the recording board that weighs 5.4g and without the 3.5g custom bracket and without the 2-gram Caddx Ant camera, and with the 49-gram, 450mah, battery front close to the battery cavity front edge, the unstable dive is shown in videos here.

The weights of the substitute components are in the pictures below. The loss of head-down torque with the Runcam Hybrid2 setup was 5.4gx6cm+(2g+3.5g)x9cm = 81.9g-cm, equivalent to having an 81.9gram-cm/30cm=2.7gram heavier tail motor.

The weights of the substitute components are in the pictures below. The loss of head-down torque with the Runcam Hybrid2 setup was 5.4gx6cm+(2g+3.5g)x9cm = 81.9g-cm, equivalent to having an 81.9gram-cm/30cm=2.7gram heavier tail motor.

What's worse was that the loss of head-down torque disrupts the level travel pitch holding, as shown in the following videos.

For the substitute Runcam Hybrid2, the solution was to modify the 450mah battery with double-sided mounting tape and Velcro to protrude 2-3cm (about 1.5-2.5cm in the horizontal component), pictured here.

When tested with Runcam Hybrid2, there was no difference in flight characteristics between 2cm and 3cm protrusion.

In the following diagram, the production build Blade Fusion 180 frame has a rotor and tail congruency as the prototype Blade 230 frame with ThumbPro(instead of Hybrid2).

The congruent tail has the moment of inertia as

>>> 0.007*(0.3**2) + 0.0048*(0.25**2)

0.00093 kg · m^2

The non-congruent motor, battery, and camera have the moment of inertia as the following calculations,

>>> #for production build plus tail

>>> 0.0418*(0.075**2)(motor) + 0.0691*(0.133**2)(battery) + 0.0019*(0.117**2)(camera) + 0.0045*(0.076**2)(FC) + 0.008*(0.1**2)(ESC) + 0.02*(0.075**2)(fuselage) + 0.00093

0.002632 kg · m^2

>>> #for prototype with Hybrid2 plus tail

>>> 0.0501*(0.0819**2)(motor) + 0.049*(0.133**2)(battery) + 0.0127*(0.127**2)(camera) + 0.0026*(0.108**2)(VTX) + 0.0026*(0.108**2)(FC at bottom plate) + 0.008*(0.110**2)(ESC) + 0.02*(0.0819**2)(fuselage) + 0.00093

0.002629 kg · m^2

So, the production build's moment of inertia is almost the same as the prototype's.

Upscaling To 4K For YouTube

The 2 videos are for comparison between uploading 1080p and 4k of the same video. If you watch them both at 720p, you will notice the difference when the craft is near the ground. The 1080p uploaded video has polygon blocks of blurs; the 4k uploaded video is closer to original video.

540p uploading can not improve the polygon blurring, even though it reduces file sizes to 60% of the originals, as shown in the file listing below. The last four entries in the file listing below show that Gyroflow output at 720p can not reduce file sizes; the 30fps file at the bottom fifth listing has file sizes reduced by 25%, not 50%, at the expense of a very choppy viewing experience; Gyroflow produced 100% smooth videos that are more choppy in actual viewing, with only 10% file size reduction in the fourth and fifth listings. The AvatarS0162 and AvatarS0163 are nearly exactly 1 minute each.

.

2.png)

.png)